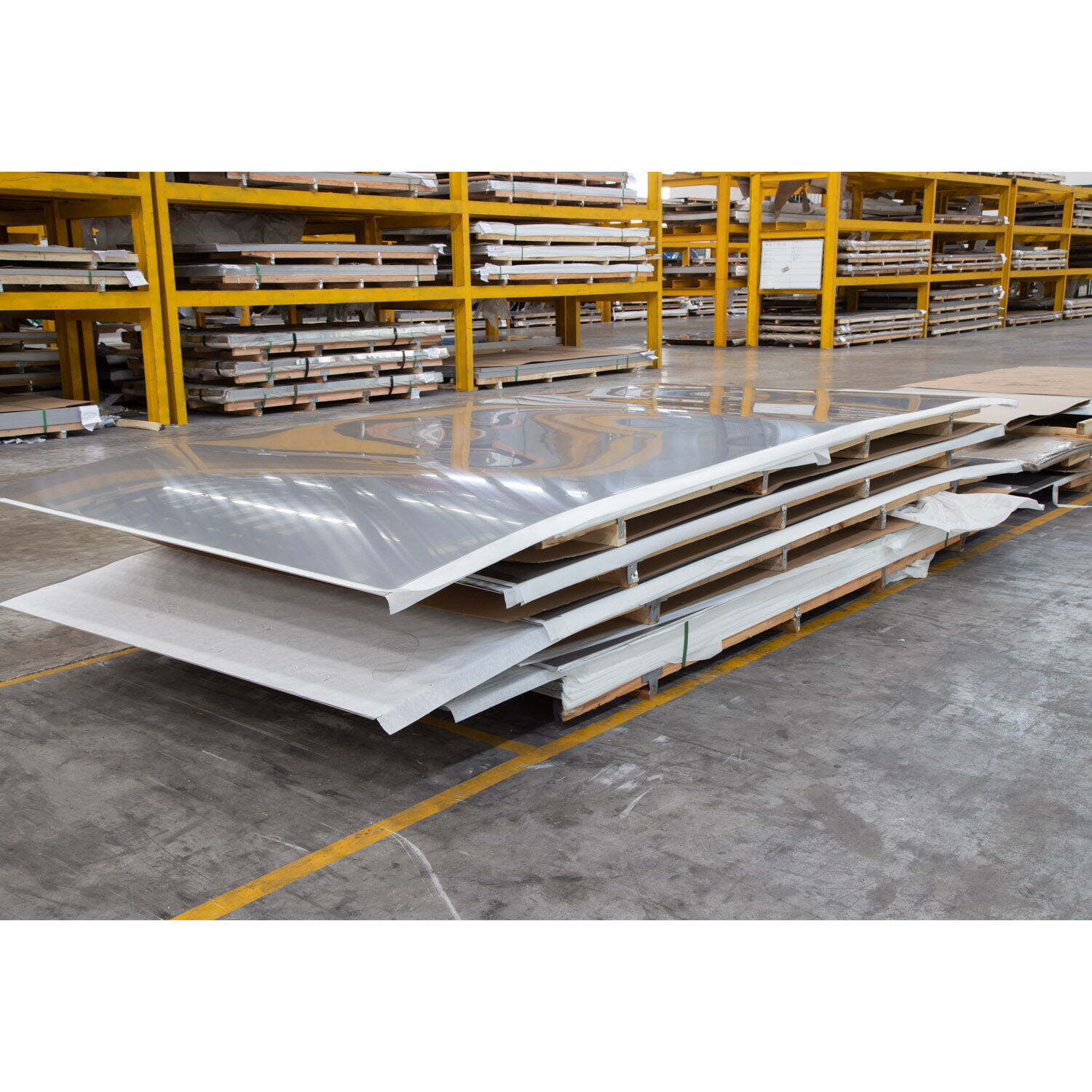

perforated stainless plate

A perforated stainless plate represents a versatile industrial component manufactured from high-grade stainless steel with precisely engineered holes or patterns. These plates are created through advanced punching or laser cutting processes, resulting in uniform perforations that serve multiple industrial and architectural applications. The plates feature various hole sizes, shapes, and patterns, offering customizable solutions for different requirements. The structural integrity of stainless steel combined with strategic perforation patterns ensures optimal performance in filtration, separation, and ventilation applications. These plates demonstrate exceptional corrosion resistance, durability, and strength, making them ideal for demanding environments. The manufacturing process involves careful consideration of factors such as hole diameter, center-to-center spacing, and open area percentage to achieve specific performance characteristics. Modern production techniques ensure consistent quality and precise dimensional accuracy, while the stainless steel composition provides excellent temperature resistance and longevity. The plates can be fabricated in different thicknesses and sizes, accommodating diverse industrial needs from small-scale filtering applications to large architectural installations.