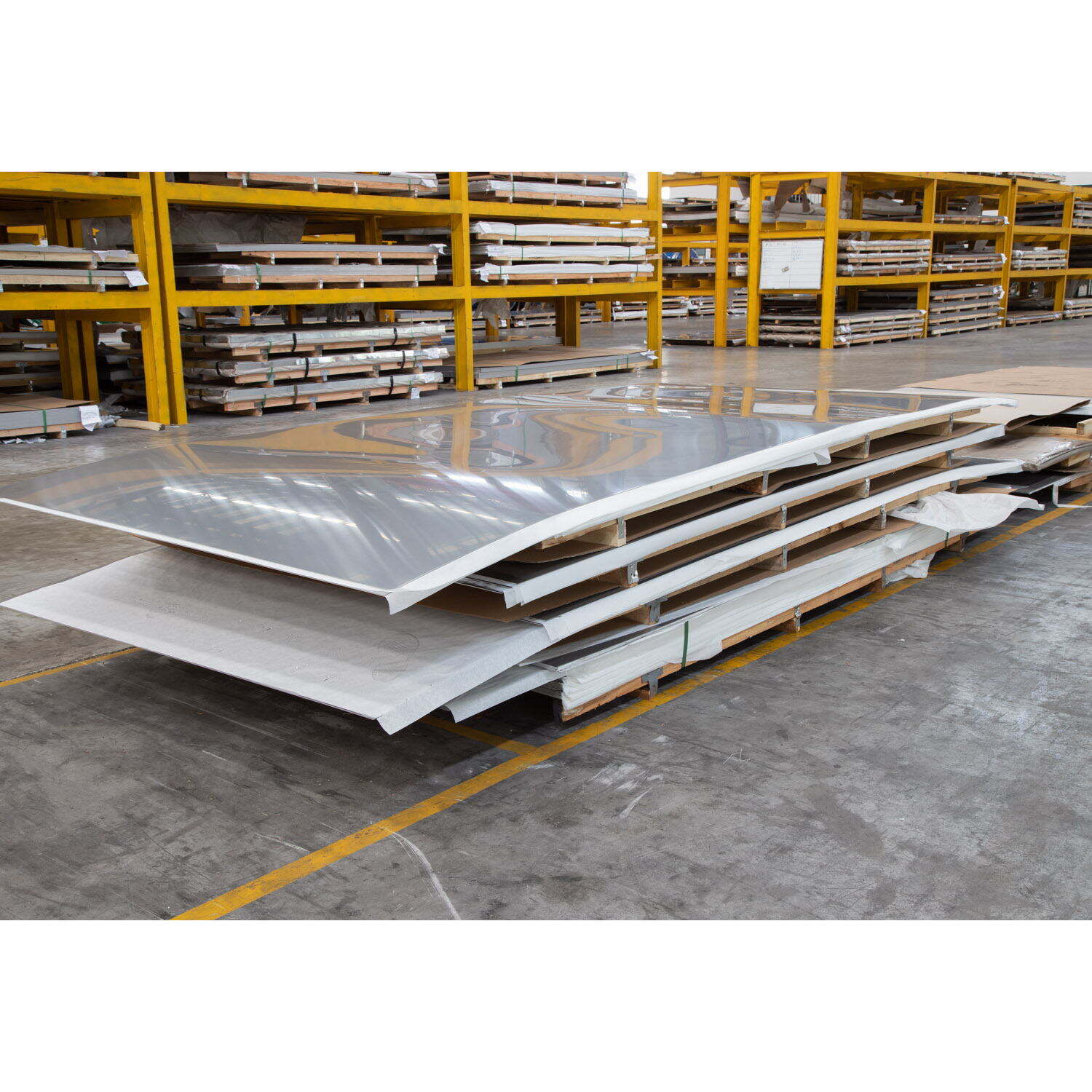

stainless sheet plate

Stainless sheet plate represents a versatile and durable material widely used in various industrial applications. This high performance metallic product combines exceptional corrosion resistance with outstanding mechanical properties, making it an ideal choice for demanding environments. The manufacturing process involves precise rolling and heat treatment techniques, resulting in uniform thickness and superior surface finish. These plates are available in various grades, including 304, 316, and 430, each offering specific characteristics suitable for different applications. The thickness typically ranges from 0.4mm to 50mm, while width and length can be customized according to specific requirements. The material exhibits excellent weldability and formability, allowing for easy fabrication and modification. Its non porous surface prevents bacterial growth, making it particularly valuable in hygiene sensitive applications such as food processing and medical equipment. The chromium content in these plates forms a self healing passive layer, providing continuous protection against corrosive elements. Modern manufacturing techniques ensure precise dimensional accuracy and consistent material properties throughout the plate, contributing to its reliability in critical applications.