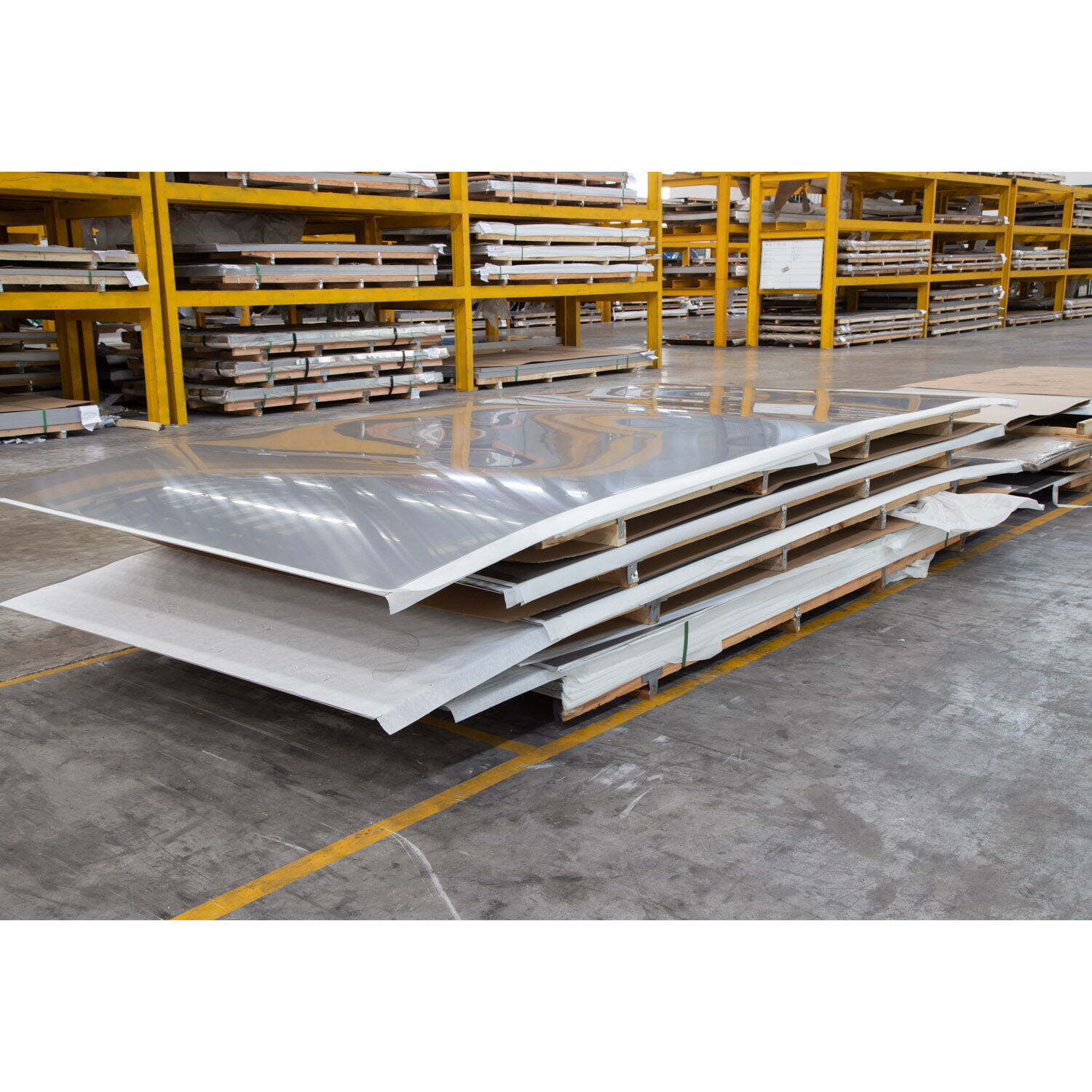

310 stainless steel sheet

310 stainless steel sheet is a high-performance austenitic stainless steel grade renowned for its exceptional heat and corrosion resistance properties. This versatile material contains approximately 25% chromium and 20% nickel, making it particularly suitable for high-temperature applications up to 1150°C. The sheet's unique composition ensures superior resistance to oxidation, carburization, and sulfidation in extreme environments. Its excellent mechanical properties remain stable even at elevated temperatures, making it an ideal choice for industrial applications requiring prolonged exposure to harsh conditions. The material exhibits remarkable formability and weldability, allowing for various fabrication methods without compromising its structural integrity. Additionally, the 310 stainless steel sheet demonstrates outstanding resistance to thermal cycling and thermal shock, maintaining its dimensional stability throughout temperature fluctuations. These characteristics make it particularly valuable in heat-treating equipment, furnace parts, chemical processing equipment, and various high-temperature industrial applications.