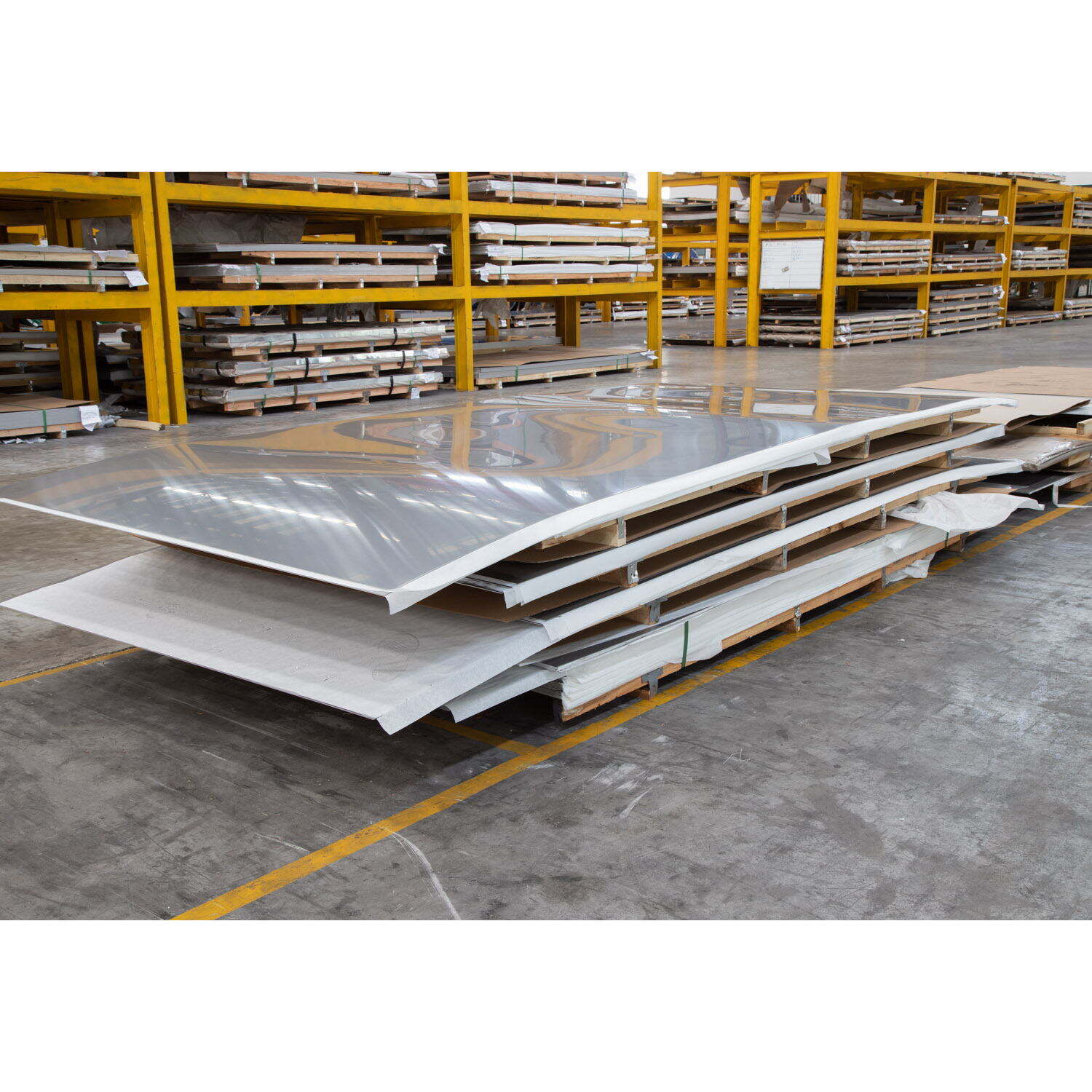

polished stainless sheet

Polished stainless sheet represents a premium grade of stainless steel material that undergoes specialized finishing processes to achieve a smooth, reflective surface. This versatile material combines exceptional durability with aesthetic appeal, making it ideal for both functional and decorative applications. The polishing process involves multiple stages of mechanical finishing, resulting in various surface finishes from satin to mirror-like appearances. These sheets exhibit superior corrosion resistance, enhanced cleanability, and remarkable durability compared to standard stainless steel variants. They are manufactured through precise controlling of grain structure and surface texture, ensuring consistent quality across the entire sheet. The material's inherent properties include excellent heat resistance, dimensional stability, and resistance to chemical exposure, making it suitable for diverse industrial and commercial applications. Common applications include architectural facades, elevator panels, kitchen equipment, medical facilities, and high-end commercial installations. The sheets can be fabricated using standard metalworking techniques while maintaining their polished finish, offering flexibility in design and implementation.