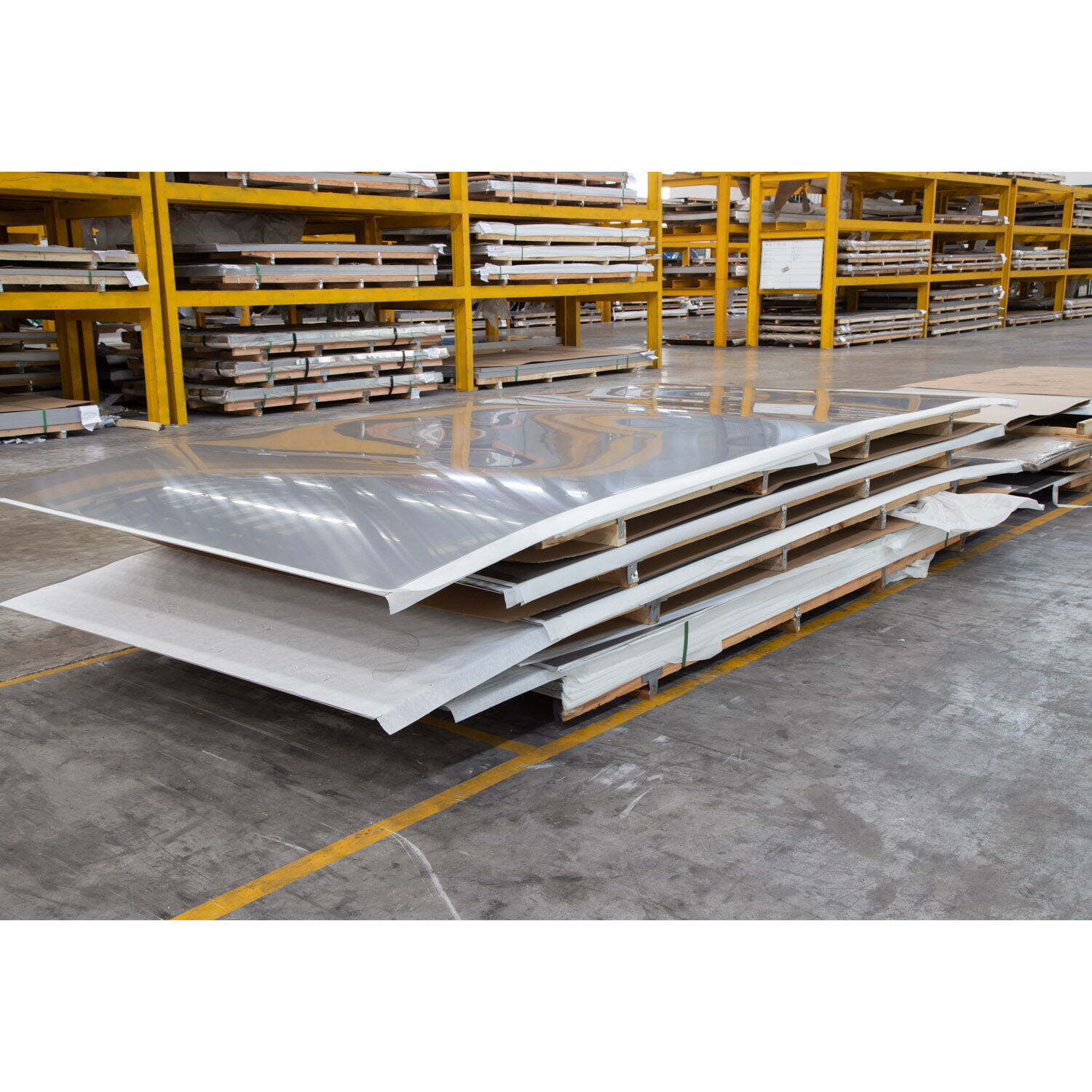

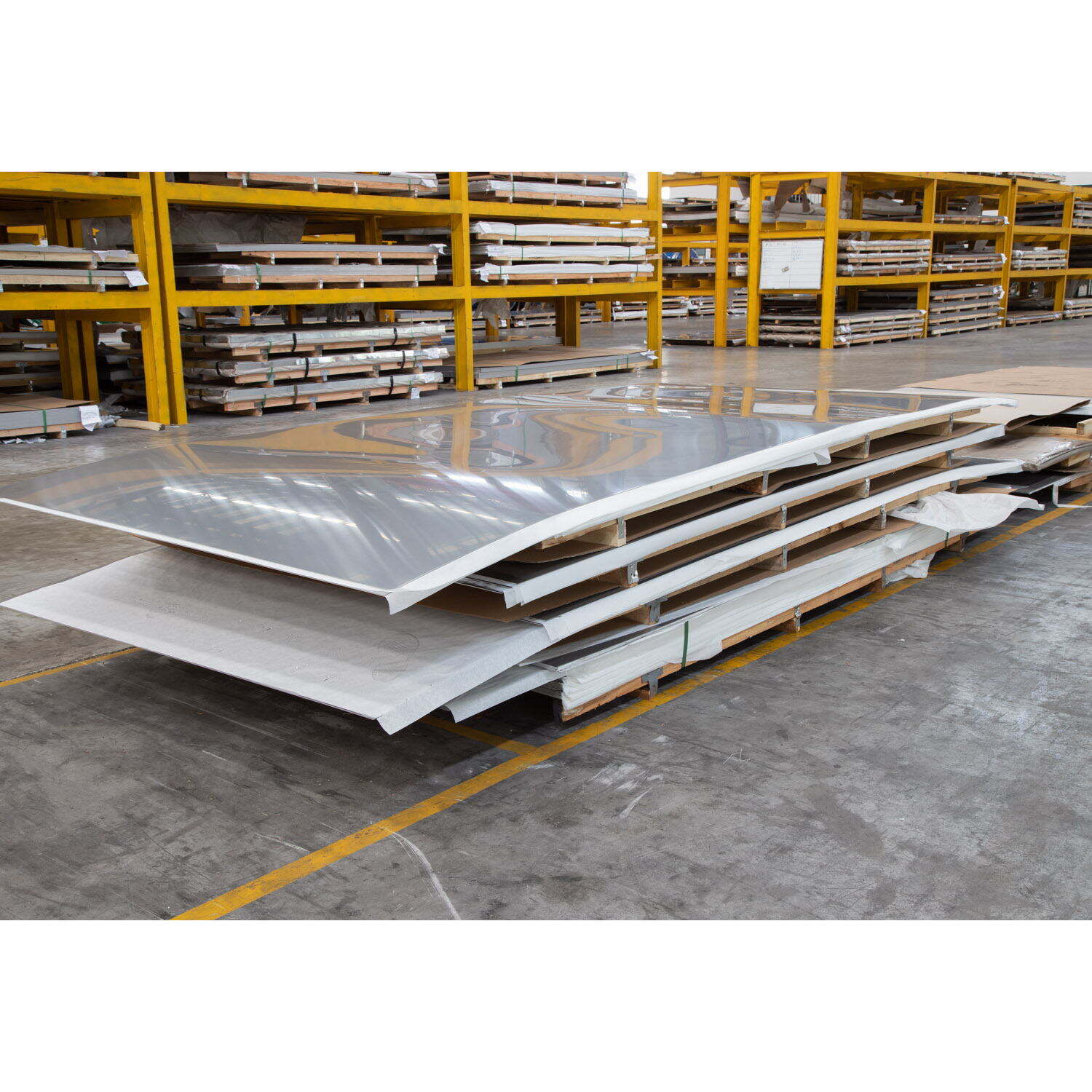

420 stainless steel sheet

420 stainless steel sheet is a high-chromium martensitic stainless steel that offers exceptional hardness and wear resistance. This versatile material contains approximately 13% chromium and 0.3% carbon, making it ideal for applications requiring both corrosion resistance and strength. The sheet undergoes specialized heat treatment processes to achieve optimal hardness levels, typically ranging from 50 to 55 HRC. What sets 420 stainless steel sheet apart is its ability to maintain excellent mechanical properties while providing moderate corrosion resistance in mild environments. The material exhibits superior edge retention and can be heat treated to various hardness levels, making it particularly valuable in cutting applications. Its unique composition allows for excellent machinability and polishability, resulting in a superior surface finish that is both aesthetically pleasing and functional. The sheet is available in various thickness options, typically ranging from 0.5mm to 50mm, accommodating diverse industrial requirements. In terms of practical applications, 420 stainless steel sheet finds extensive use in surgical instruments, knife blades, industrial cutting tools, and food processing equipment where both durability and cleanliness are paramount.