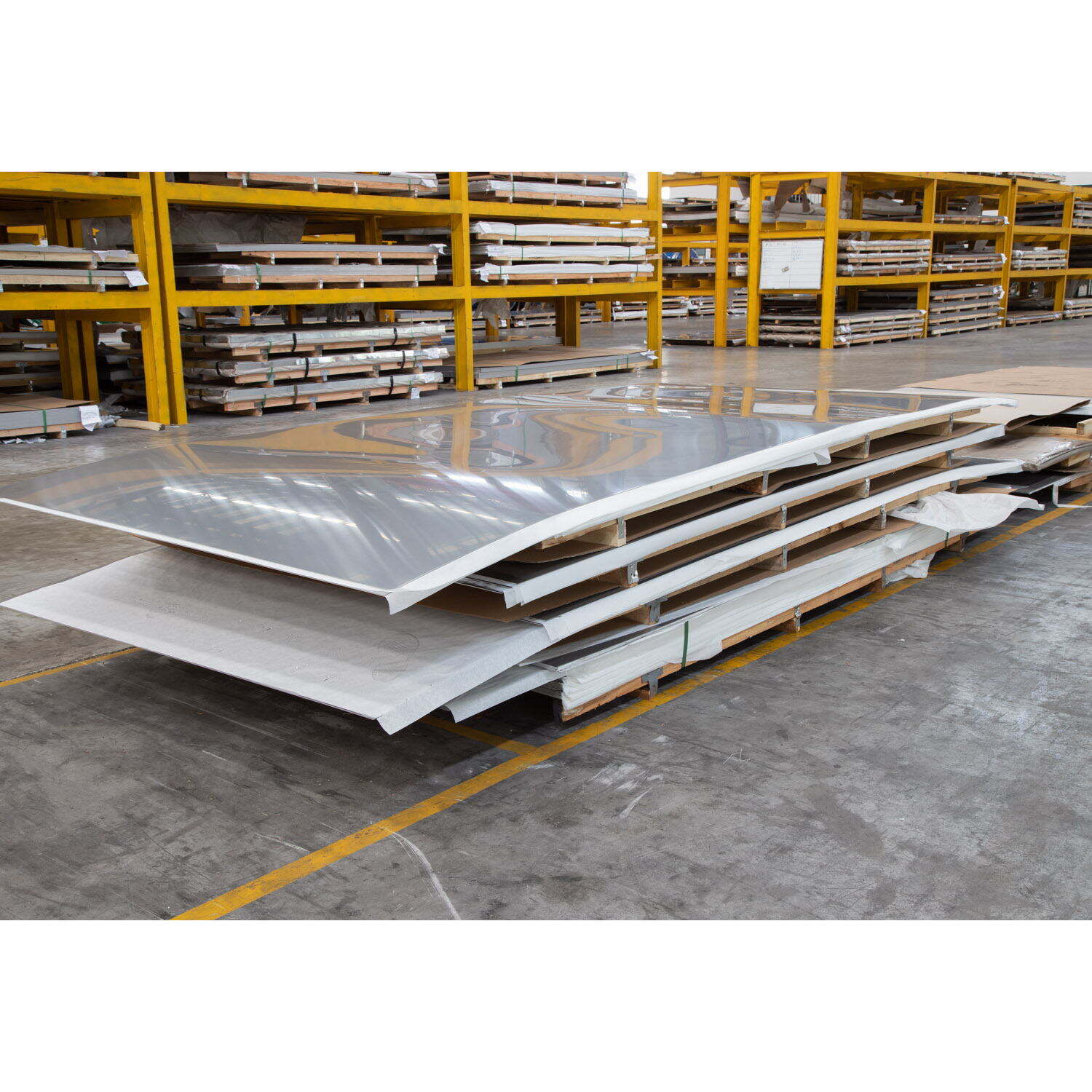

2mm stainless steel sheet price

The 2mm stainless steel sheet price represents a crucial consideration for industries requiring durable, corrosion-resistant materials. This specific thickness offers an optimal balance between strength and workability, making it a popular choice across various applications. The pricing of 2mm stainless steel sheets is influenced by several factors, including market conditions, material grade, surface finish, and quantity ordered. Premium grades like 304 and 316 typically command higher prices due to their superior corrosion resistance and mechanical properties. The current market sees prices ranging from $80 to $150 per square meter, depending on these variables. These sheets find extensive use in architectural cladding, kitchen equipment, industrial tanks, and automotive components. The manufacturing process involves hot rolling followed by cold rolling to achieve precise thickness and surface quality, ensuring consistent material properties throughout the sheet. Modern production techniques have optimized cost efficiency while maintaining high-quality standards, making these sheets more accessible to various industries. The global supply chain and raw material costs significantly impact the final pricing, with factors such as nickel content and processing requirements playing crucial roles in price determination.