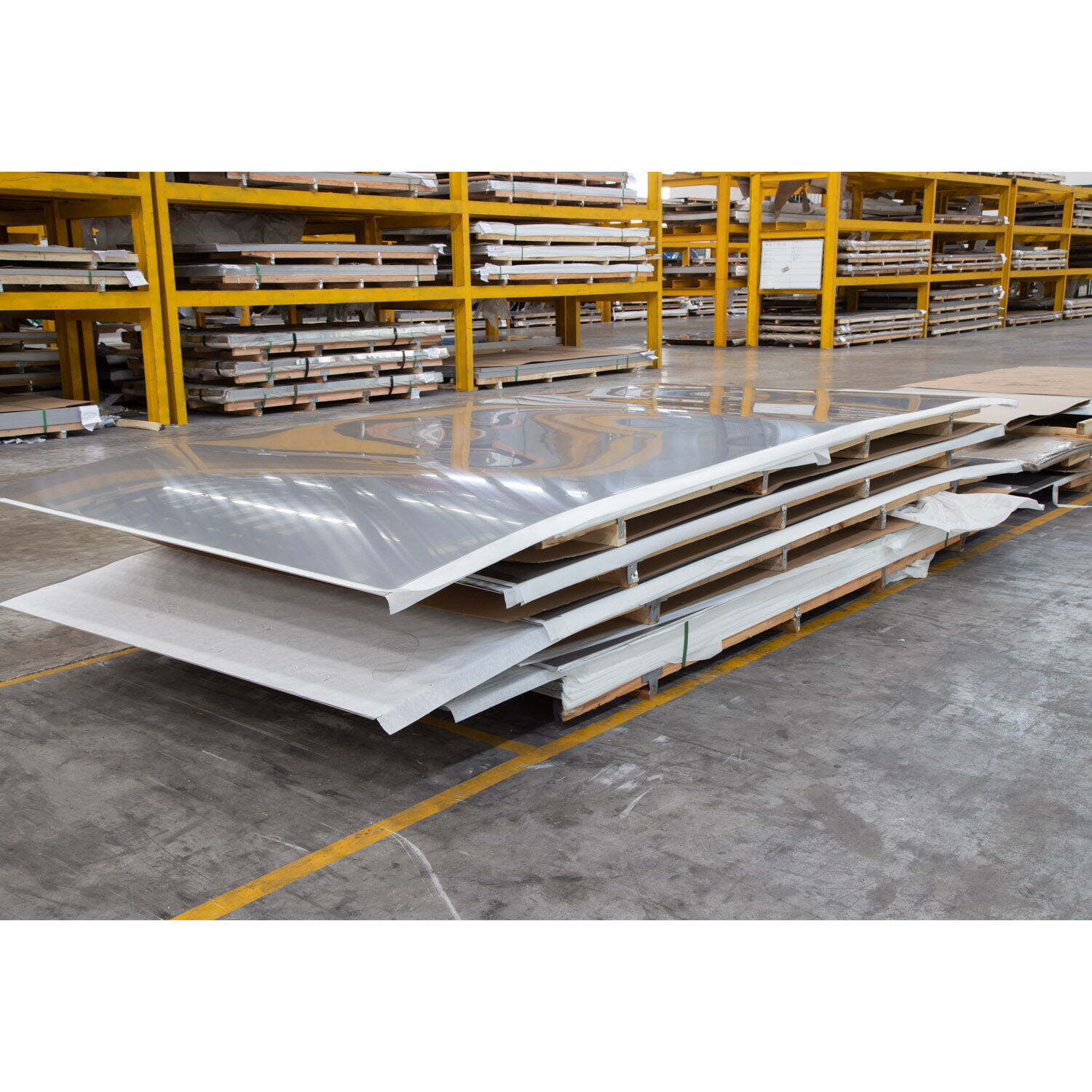

17 4 stainless plate

The 17 4 stainless plate is a premium grade precipitation hardening stainless steel that combines exceptional strength with outstanding corrosion resistance. This versatile material, also known as Type 630 stainless steel, features a martensitic crystalline structure that enables it to achieve remarkable hardness through heat treatment while maintaining its dimensional stability. The plate exhibits an optimal balance of mechanical properties, including high tensile strength, excellent yield strength, and superior hardness levels that can reach up to 45 HRC. Its chromium content of approximately 17% and nickel content of 4% contribute to its exceptional resistance to various corrosive environments, making it ideal for demanding applications. The material's unique composition allows it to maintain its structural integrity across a wide temperature range, from cryogenic conditions to elevated temperatures up to 600°F. This stainless plate is particularly valued in industries where precision, durability, and resistance to harsh environments are crucial requirements.