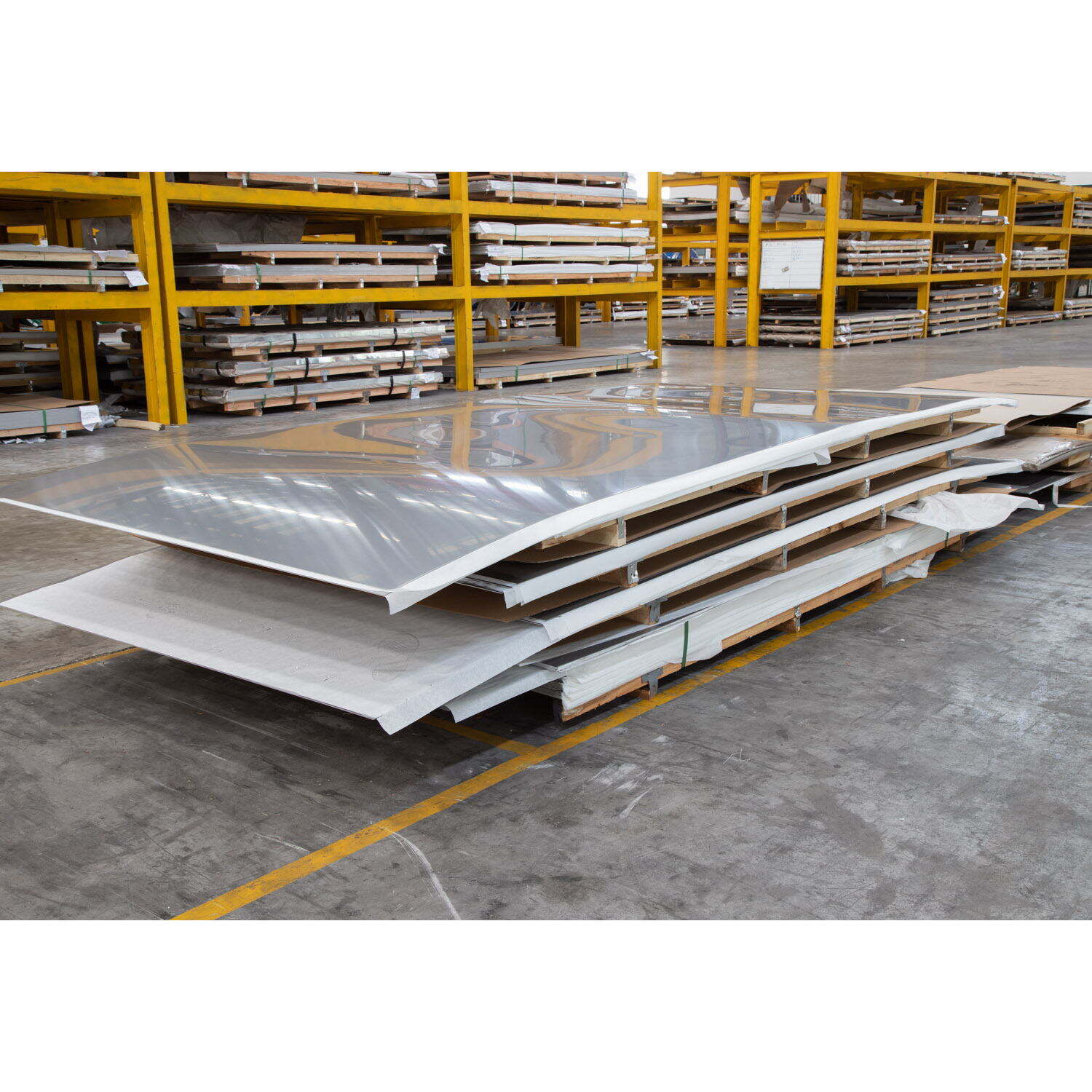

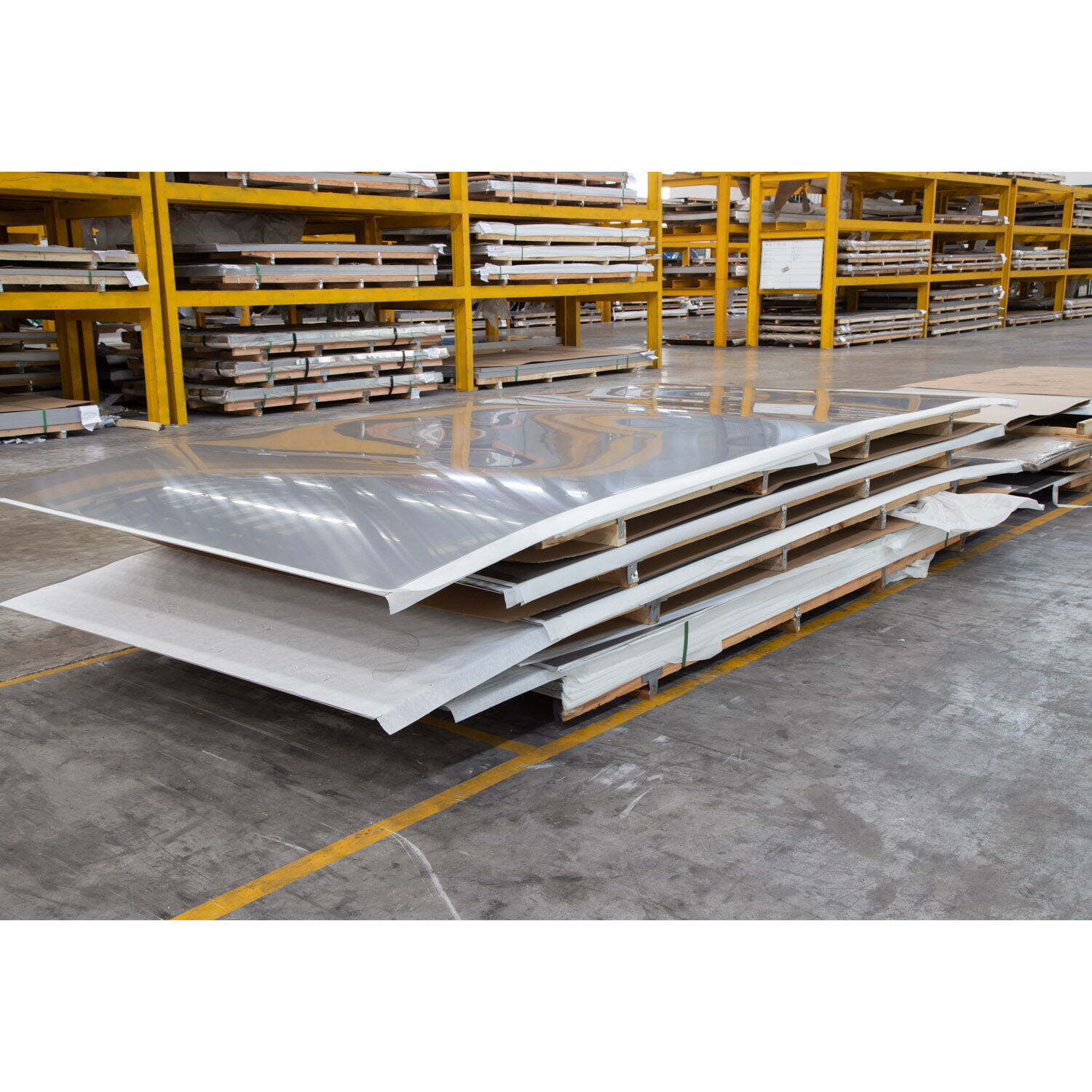

17 4 stainless steel plate

17-4 stainless steel plate is a high-strength, precipitation-hardening stainless steel that offers an exceptional combination of mechanical properties and corrosion resistance. This versatile material, also known as Type 630, contains approximately 17% chromium and 4% nickel, along with copper and other alloying elements that contribute to its superior performance characteristics. The plate undergoes a specialized heat treatment process that develops its remarkable strength while maintaining good ductility. With a tensile strength ranging from 150,000 to 200,000 PSI depending on the heat treatment condition, it provides excellent resistance to general corrosion, stress corrosion cracking, and oxidation at temperatures up to 600°F. The material's unique composition allows it to achieve high strength levels through relatively simple heat-treatment procedures, making it particularly valuable in applications requiring both strength and corrosion resistance. Common applications include aerospace components, chemical processing equipment, nuclear reactor components, oil field equipment, and various structural applications in marine environments.