carbon welded steel pipe

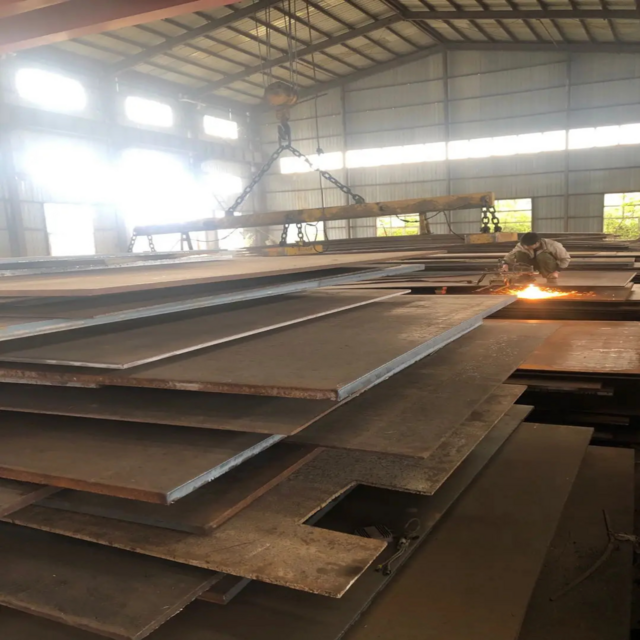

Carbon welded steel pipe represents a crucial component in modern industrial infrastructure, combining durability with cost-effectiveness. Manufactured through a precise welding process, these pipes are created by forming carbon steel sheets or strips into cylindrical shapes and joining them along a longitudinal or spiral seam. The welding process, typically utilizing electric resistance or fusion welding techniques, ensures a robust and reliable connection. These pipes feature varying wall thicknesses and diameters to accommodate different pressure ratings and application requirements. The carbon content in the steel composition provides excellent strength and structural integrity, making these pipes suitable for numerous industrial applications. They demonstrate remarkable resistance to mechanical stress, pressure variations, and environmental factors. The manufacturing process includes rigorous quality control measures, including radiographic testing and hydrostatic pressure tests, to ensure compliance with international standards. Carbon welded steel pipes are extensively used in oil and gas transportation, construction projects, water distribution systems, and various industrial processes. Their versatility extends to both above-ground and underground installations, with appropriate coating systems providing additional protection against corrosion and environmental factors.