welded 304 stainless steel tubing

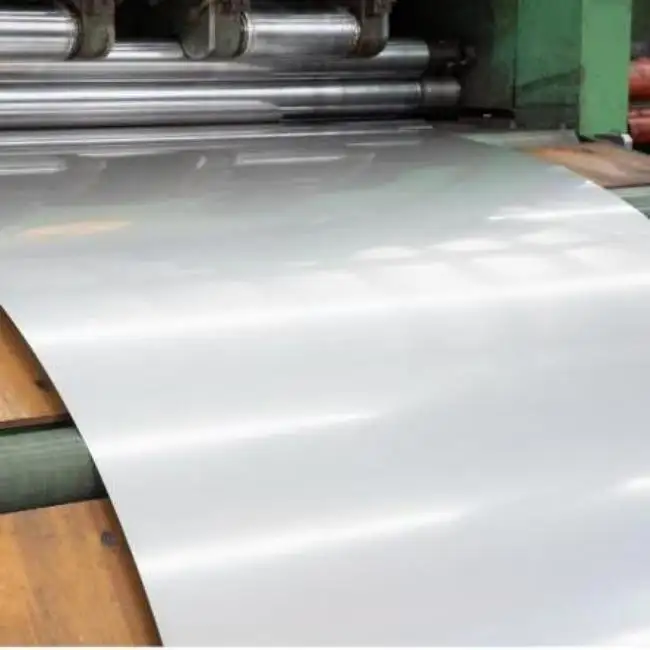

Welded 304 stainless steel tubing represents a cornerstone in modern industrial applications, combining superior corrosion resistance with exceptional durability. This versatile material is manufactured through a precise welding process that joins high-grade 304 stainless steel sheets into seamless tubes. The resulting product features an optimal blend of chromium and nickel, typically 18% and 8% respectively, which creates a self-healing passive layer that provides outstanding protection against corrosion. These tubes are widely utilized across various industries, from food processing and pharmaceutical manufacturing to chemical transport and architectural applications. The welding process employs advanced technology to ensure consistent seam quality while maintaining the material's inherent strength and resistance properties. The tubes can be produced in various dimensions, with wall thicknesses ranging from 0.5mm to 12mm and diameters spanning from 6mm to 2000mm, offering exceptional flexibility in application. The 304 grade's excellent formability and weldability make it particularly suitable for complex installations and custom configurations, while its hygienic properties make it ideal for applications requiring strict cleanliness standards. The material's ability to withstand temperatures from cryogenic levels to 870°C further enhances its versatility in both high and low-temperature applications.