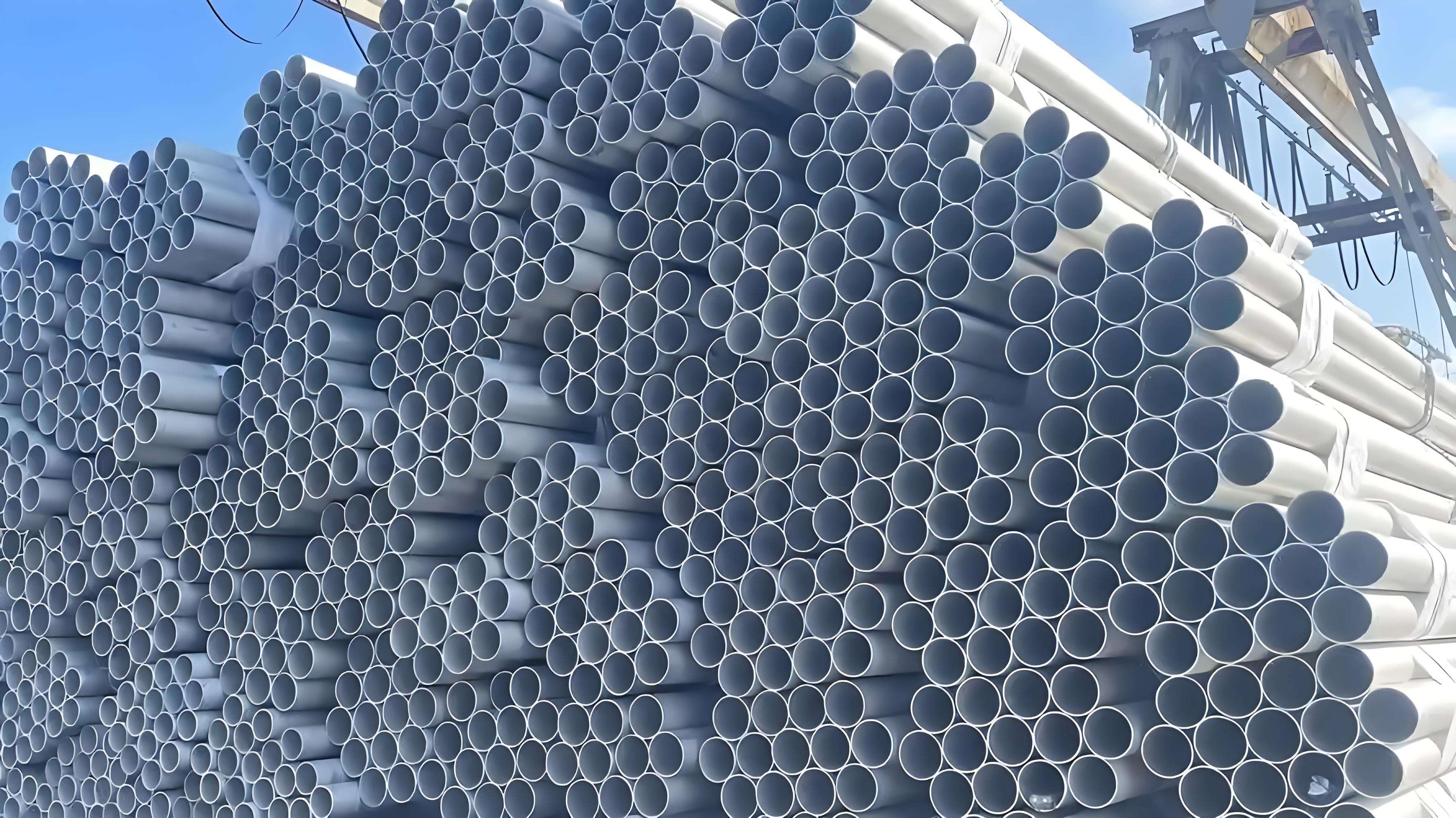

welded steel tube

Welded steel tube represents a crucial component in modern industrial and construction applications, manufactured through sophisticated welding processes that join steel strips or plates into robust tubular structures. This versatile product combines strength, durability, and cost-effectiveness, making it an ideal choice for numerous applications. The manufacturing process involves precise rolling of steel sheets followed by automated welding along the seam, creating a seamless-looking joint that maintains structural integrity. These tubes are available in various dimensions, wall thicknesses, and grades, accommodating diverse project requirements. The production methodology employs advanced technology, including high-frequency welding or electric resistance welding, ensuring consistent quality and reliable performance. Modern welded steel tubes undergo rigorous quality control measures, including ultrasonic testing and hydrostatic pressure tests, to verify their structural soundness. They excel in both load-bearing applications and fluid transportation systems, offering exceptional resistance to external pressures and environmental factors. The versatility of welded steel tubes extends to their finish options, including galvanized, painted, or bare steel surfaces, each serving specific environmental conditions and application requirements.