welded stainless steel pipes manufacturer

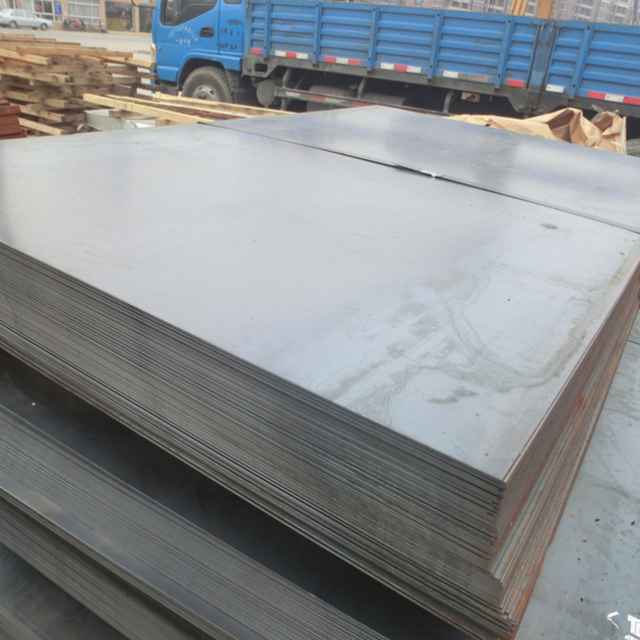

A welded stainless steel pipes manufacturer represents a cornerstone in modern industrial infrastructure, specializing in the production of high-quality welded pipes through advanced manufacturing processes. These facilities utilize state-of-the-art welding technology, including automated TIG and MIG welding systems, to create seamless joints that meet stringent industry standards. The manufacturing process begins with premium grade stainless steel sheets or strips, which are carefully formed into cylindrical shapes and welded along the longitudinal axis. The facility employs sophisticated quality control measures, including radiographic testing, ultrasonic inspection, and hydrostatic pressure testing, to ensure each pipe meets exact specifications. These manufacturers typically offer a diverse range of pipe sizes, from small diameter tubes used in household applications to large industrial pipes, with wall thicknesses varying according to specific requirements. The production capabilities often include various stainless steel grades, such as 304, 316L, and 321, each suited for different environmental conditions and chemical exposures. Modern facilities also incorporate advanced surface treatment processes, including pickling and passivation, to enhance corrosion resistance and ensure optimal performance in diverse applications across industries such as petrochemical, food processing, pharmaceutical, and construction.