electric resistance welded steel pipe

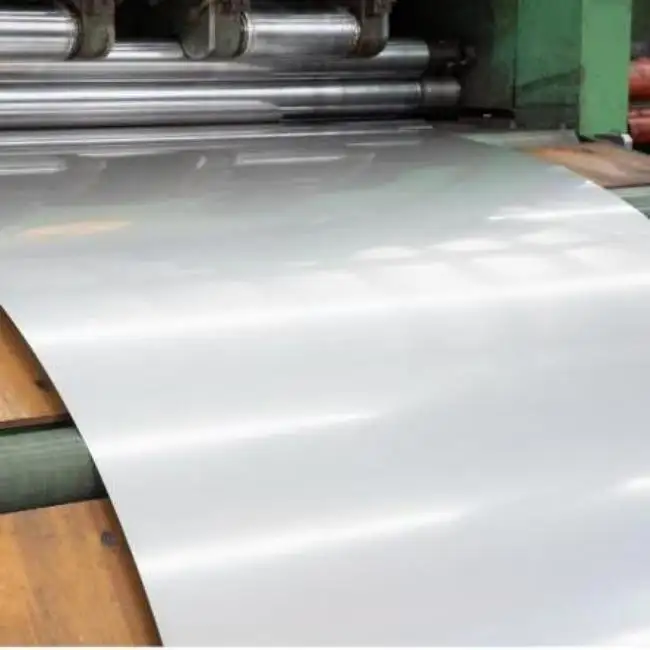

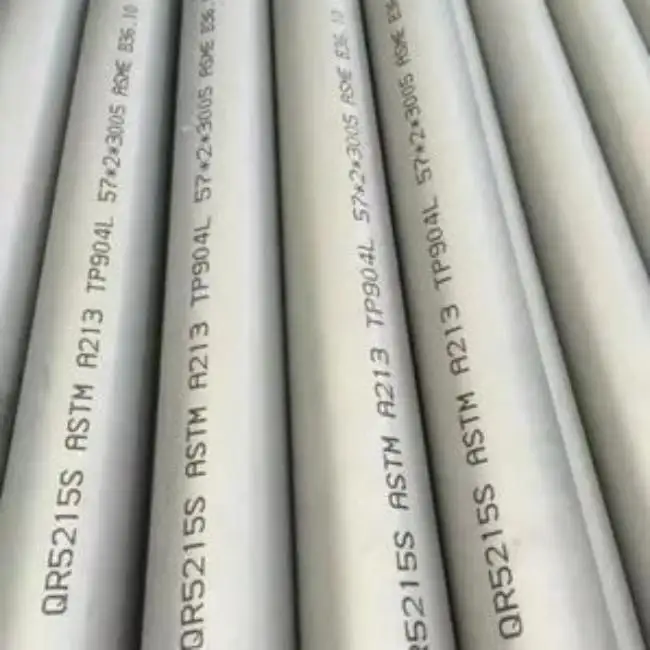

Electric resistance welded (ERW) steel pipe stands as a cornerstone in modern industrial applications, manufactured through an innovative process that combines precision engineering with efficient production methods. The manufacturing process involves continuous steel strip being cold-formed into a cylindrical shape and welded along the seam using electrical resistance heating. This creates a strong, uniform weld without the need for additional filler material. The pipe undergoes thorough quality control measures, including ultrasonic testing and hydrostatic pressure testing, ensuring structural integrity and reliability. ERW steel pipes are produced in various sizes, ranging from small diameter tubes to large industrial pipes, with wall thicknesses carefully calculated to meet specific pressure and load requirements. These pipes excel in applications requiring consistent quality and dimensional accuracy, making them ideal for fluid transportation, structural support, and mechanical applications. The controlled manufacturing process results in pipes with superior surface finish, precise dimensional tolerances, and excellent straightness, characteristics that are crucial for modern construction and industrial applications. ERW steel pipes also demonstrate remarkable cost-effectiveness compared to seamless pipes, while maintaining high performance standards in most applications.