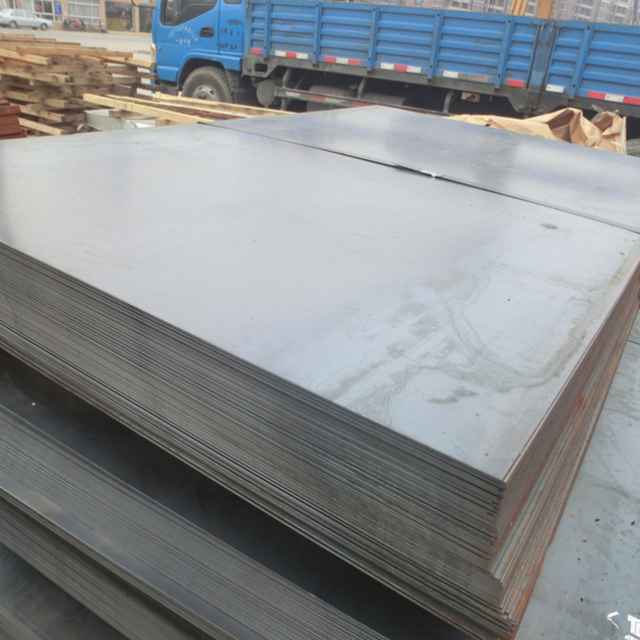

low carbon steel sheet metal

Low carbon steel sheet metal is a versatile and widely used material in manufacturing and construction industries, containing carbon content typically ranging between 0.05% and 0.25%. This composition provides an optimal balance of strength, formability, and cost-effectiveness. The material undergoes careful processing to achieve uniform thickness and surface quality, making it ideal for various applications requiring consistent performance. The manufacturing process involves hot rolling or cold rolling techniques, resulting in sheets with precise dimensions and excellent surface finish. Low carbon steel sheet metal exhibits superior weldability and machinability, making it easy to work with using conventional tools and equipment. Its inherent properties include good ductility, allowing for complex forming operations without material failure. The material also demonstrates remarkable resistance to everyday wear and tear, making it suitable for both indoor and outdoor applications. In terms of market availability, low carbon steel sheet metal comes in various thickness ranges and surface treatments, offering flexibility in application-specific requirements. The material's adaptability to different coating processes, including galvanization and powder coating, enhances its corrosion resistance and aesthetic appeal.