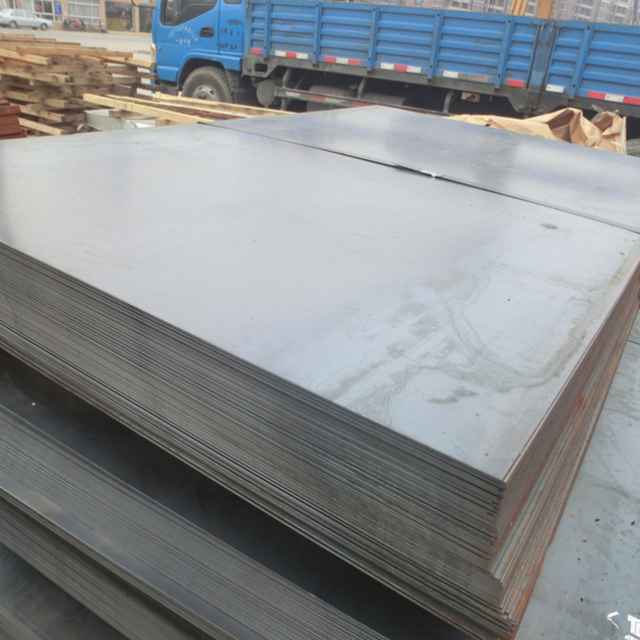

Versatile Applications and Processing Capabilities

Cold rolled carbon steel sheet demonstrates remarkable versatility across diverse manufacturing applications, supported by its excellent processing capabilities. The material's combination of strength, formability, and surface quality makes it suitable for everything from architectural panels to consumer appliances. Its superior weldability allows for various joining methods, including resistance welding, MIG welding, and laser welding, with minimal distortion and consistent joint quality. The material's compatibility with various surface treatments, including galvanizing, phosphating, and modern coating systems, enhances its corrosion resistance and aesthetic appeal. This versatility extends to its machinability, allowing for precise cutting, punching, and drilling operations with minimal tool wear. The material's consistent properties ensure reliable performance in automated manufacturing environments, supporting high-speed production lines and complex fabrication processes.