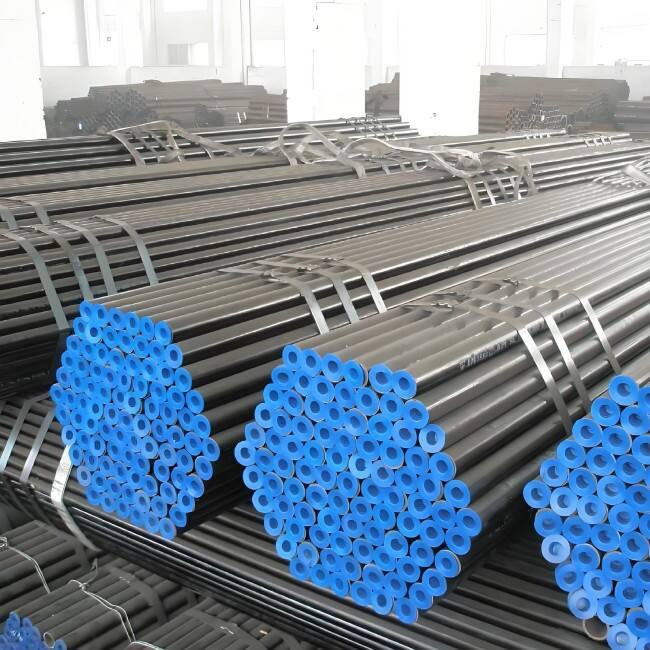

Ipayipe yesele yebhayisikhalo A53

I-pipe yaseleswa yesiyo sivele kahle ngokushesha, esebenziswayo ngokuphelele kwi-material engu-carbon steel, okusebenzisa kakhulu kuzikwezelo zokugcina, ukubhawula nokusasaza noma zonke izinto.

- Ukuhlaziywa

- Imikhiqizo Econyiwe

B amagcinzelo amabili kwezindlela lestelepipe yesiyezi

1.Inqaku: Istelepipe yesiyezi yiyo ngestelepipe esingafanele ngemali okwesibhedlela nebhokisi (umali wesibhedlela wakhiwa ukuthi zikhumile kokugcina emfuneko 2.06%), kunjalo akungavunyelwe amanani apho ahlukene, isilayishe, isulifhur, isifolofhosi nalo mabele.

2.Amagcali: umnotho omkhulu, upheshefuntela olungapheli, imali engapheleleyo, kufanele ukuba uhlalekile nokubhala nokusondeza, kodwa uhlobo oluncane lokuhlola (kufuneka kuhlonishwe).

Ukubopheka kwestelepipe yesiyezi

1.Kusapho kwesiphumo somncedisi

①Umgwangari Weseleshi WeCarbon Steel

Ingenziwe ngokusebenzisa umncedisi wohhala noma ukulingana nokuncedisi, eyayiphi ingxenye yomthengi.

Amasiko: uphakamiso olungileyo lokuhlola, sibonisa kuhluke kanye nezintlonkana ezincane (njengeboilers, idabhu yesikhathi esidingeni).

Iindlela zakho: okupheli kakhulu.

②Umphoyisi WesiKholoni Esikhishweyo

Ikhishwe kwiplate yesikholoni noma istrip esikhishweyo (umsebenzi omunye: ukukhisha ngokwesinti, ukukhisha ngokubungene).

Amasokiso: umdlulelo womphoyisi okuhle, imali encinci.

Amahlobo: uphenyo oluncane lokuhlola amagama, isiqephu sesikhisho singabonakali sibekelene nesinye isigaba esincinane.

2.Kuhluke kwezinkomo zesiKhholoni

①umkhathalizi wesiye esijwayelekileyo (C ≤ 0.25%)

ngokushesha Q235, A106 Gr.B, ukusentisisa okukhangelwe, kuhluke ukusondezela, usetyenziswa ngokwesibonelo somahlaba, amaphipha amadlozi kunye neziphi.

②Umkhathalizi wesikhathi semasungu (0.25%

ngokushesha i-45# steel, inqanawe enkulu, usetyenziswa ngokubheka izinhlelwa zokugcina, izixhasi.

③Umkhathalizi wesikhathi esikhulu (C>0.6%)

Ukuphakamiswa okukhulu kodwa ukusibezelana ngenqanawe, kuzokugcinwa ngokubanzi kwiindlela ezikhona, amathuluzi ophambili.

Amagama emkhulu nokubungazwa

1.Amagama anguqulelwano

ASTM A53/A106 (Isitandawo SaseMerika), API 5L (umgwaneni wemfene wezithuthi), EN 10255 (Isitandawo SeYurophu).

2.Isitandawo Sesayina

GB/T 8162 (umgubho wokuhlola), GB/T 3091 (umgubho omkhuhlane), GB/T 9711 (umgubho wesithathu somlilo nomsebe).

3.Amagrazi ezingabango

Q235, 20#, 45#, ASTM A106 Gr.B, API 5L X42-X80 nokulandelayo.

Isicelo amasayithi esidingeni sokugcina

1.Isigaba sokuqhuba: amaphrofayile, ukususa umkhondo wezindlela.

2.Amadladisi wesiBhulandlela nemasimu: umaphu ophathelwe, amadevayeli yokuhlola.

3.Ukugcina imikhrimi: amashafu, amabhara lezikhatsi zomandla.

4.Umnotho wenqanawe neenyathi: indaba yobuthi, umkhuhlane womdlalo.

5.Ingeni yokubaluleka: ukuhlala, ukususa, amaphu ezihlabeleleyo kwezintsha.

Amahlelo nokuba Ayishayamileyo kwePhayipe esincinci

1.Amagcinyi:

Ukuphuma kucabangeleka, kucabanga ngokulandel’ isidingo;

Ukuhlala okungakuvumelanga (unomgomo ongayiqashwa, uqondlezela, ungacutshwayo);

Isidingo esingiseko, ukukhathala ngokubheke;

2.Amayiselo:

Kungafanele ukufisela (kudinga ukwaziwa amanzi, ukuba i-paint okanye ukusetyenziswa nge-plastic);

Ukushayelekwa kwamalayithi akuyinketho.