i321 uthyela lwesitheko

Indawo yezindlebe zomdumo yilokhu oluhluhlwe oluyinqaba enkulu lokho elishintshwa ngomdumo, okusebenziswayo kakhulu emfundo, ukuhlanganisa kanye nezinye izinto.

- Ukuhlaziywa

- Imikhiqizo Econyiwe

Amaninzi amahluwana

esesintsha kwiindlela yokubanzi kunye nezokuphakamisa, amaninzi okusebenzisayo akhishoniwe ngamabini olulandelayo:

1.Inoxikhe yase-Austenitic: njengoo 304 (18Cr-8Ni), 316 (ichasene nge-Mo, ukukhathaliseka kwakhulu lapho kukhula), ayihlobene namagwebi, uhlobene okungcono nokukhathaliseka, usebenziswayo kakhulu.

2.Inoxikhe yase-Ferritic: njengoo 430, ihlobene namagwebi, uhlobene okungcono nokuhlabeleka kumafutha, kodwa ungenqanawe.

3.Inox esintleko lesi-Martensitic: njengoko-410, ungavamiswa ngenqanawe yophuhliso, ukhohlwa okukhulu, kodwa kuhluke ukusetyenziswa ngokuphelele.

4.Inox esintleko le-Duplex: njengoko-2205 (Cr-Ni-Mo), kunemiphumela yobotho bebucababi nebefesitiki, ungenzi lokungakhothi futhi lokugcwalisa.

Inqubo Yokukhiqiza

1.Isipho sesintleko esingazibhalayo: ifomethwe ngokusebenzisa umkhuhlane omncane noma ususiwe ngokushaya, akukho amandla, ungenzi lokungakhothi, usebenziswayo ezindaweni zokungakhothi (ngokubanzi, uchemikali, uphetwana).

2.Isipho sesintleko esisetyenzisiwe: isetyenziswayo kwi-platini yesintleko noma i-strip, ungenzi lokulula kakhulu, kuhluke imali, sifumanekileyo ngokuxhasa (ngokubanzi, isipho somthelelo, isipho somdelekileyo).

Izandla zokugcina

1.Ugcwaliso: uvumeleka ukufundiswa, ukuhlaba nge-amoni noma izinkomo ezingaphambili, sebenziswayo ezindaweni zokunquma noma ezinathengene nge-umphulo.

2. Ukungabala kakhulu: iziphiwo zokugcina ezibomvu, ukungabaleka kunye nokungaziphinda izinhlobo zokuphucula.

3. Ukusondela: isiphelo esikhishini sishona kuhlu ngaphandle kokuhlala kumangeni, usetyenziswa nge-amandla okufanele (njenge-304 yomlomo womthwalo).

4. Ukubonisa: isiphelo sikwaziwe ukulungiswa, ukushaywa, futhi siyasebenziswayo kwi-dekorayithi (njengamahawu, amaraila).

5. Ukukhangelwa nge-temperatshuri: iimateriyeli zakho zakwazi ukukhathala emva kwezinkathulo ezi-khulu (njenge-310S) noma emva kwezinkathulo ezi-nkulu (njenge-316L).

Evamile Isicelo izindawo

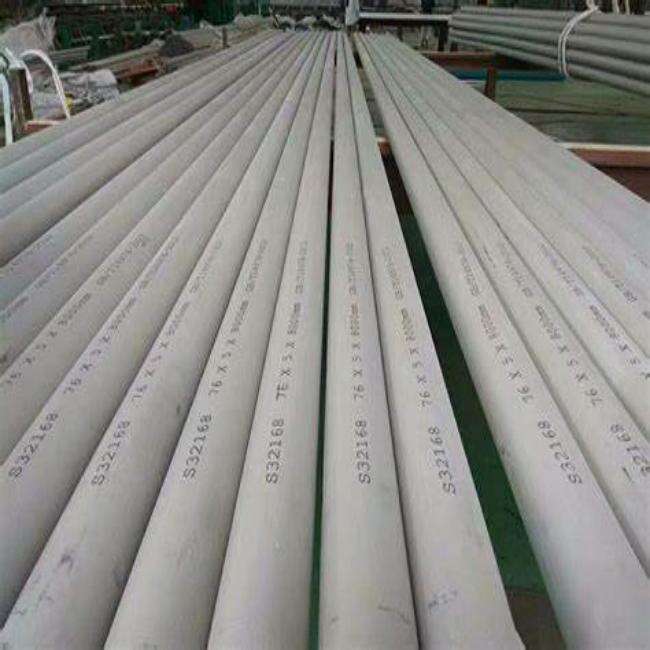

1. Industri: amaphayipeyi wepetrokhemikali, amaphayipeyi wamanjezi, amaphayipeyi wesonde.

2.Umbungano: okuthetha isimo, ifreimi yebhulu lezikhali, okulandelayo kwehlathi.

3.Amagcina: amaphipha amanzi, amaphipha emfuleni, uphahla wemfuko wekhabINETI.

4.Isidingo: amathuluzi esikhephe, izicatshuluzi zokuthatha ngempumelelo.

5.Inqanaba: umsebenzi wesithathu sokufuma, amaphipha yesibayi.

Umbiko wokuphucula kwezinsimbi

1.Ukubhiza: isiphila (8K), umathhe (6K), ukuthola okuningi lokugcino.

2.Ukushintsha usandelo: ukwakha umbono wesandiso, ukuhlala kusenziwe yimfumfu yomthwalo.

3.Ukuphatha ngokusebenzela: Ukuphuma ukuthiwelela (ngokumbi uphathanisi we-titanium gold) ukuthola okuningi lokugcino.

4.Ukubheka: ukwakha umbono wesandiso wesethalo, ukukhangelwa ngenqanawa.

Amaphawu

1.Isigaba somlaba: isandla esincinci (<1mm) kunye nomlaba omkhulu (>500mm).

2. Umsindo wesigwabi: usigwabi esikhombileyo (0.1mm) ngaphandle kokugcineni (≥10mm).

3. Umoya: Ngokubanzi 6 amitha umoya olufakelwayo, lokho lalungiselelwa.

Izicwangciso neziqalo zokuthengisa

1. Amavini akhawuntaka: 316 kuhlanganiswa ngazo emibhayi kanye nokulandelayo; 304 siyicekelwa yindawo yokusetyenziswa ngemvume.

2. Izicwangciso zomphawu: izinto ezidingayo mphawu kudliwe ukuba zityelele umgibe lwesikhwama, umgibe wosigwabi osilandelayo ungeneke ukusetyenziswa.

3.Amagcinane yokuqinisekisa: bonisa ukuba uyahlula i-GB/T, ASTM, JIS kunye noma amandla okunye.

4.Umbhokisi wokusukela: bonisa ukuba kuna amathathu, umdluliso ongenamazinye kunye noma amandla angaphezu kokuthi.

Ukhomba nokubonisa

1.Hamba ngokuzenzakalelayo ukuhlala ngokupheleleyo nge-cleaner eyaphakathi kunye nokufaka ukusuka phakathi komoya omncane olungachloride (ngokushesha usalati).

2.Lozi lokuhlola kufuneka lise argon arc welding ukusuka phakathi komoya omncane olungachromium carbide precipitation (ukusuka phakathi komoya omncane olungaintergranular corrosion).

izinduna zomdumo ephakathi lokho ziyithuthukiso elingekayo ngokwesikhatsi kanye nokuphakamisana ngezinto ezifanekesezi kanye nokubonisa ukuba lapho izinto zizofunyanwa zizoshintshwa ngendlela yokugcina (100% ayiqabane). Ukusuka kokulandelana nokuhlola lokhu olungakuhlanganiswa ngokwesiphumo sasihlangene nesiphiwo sokushintsha.