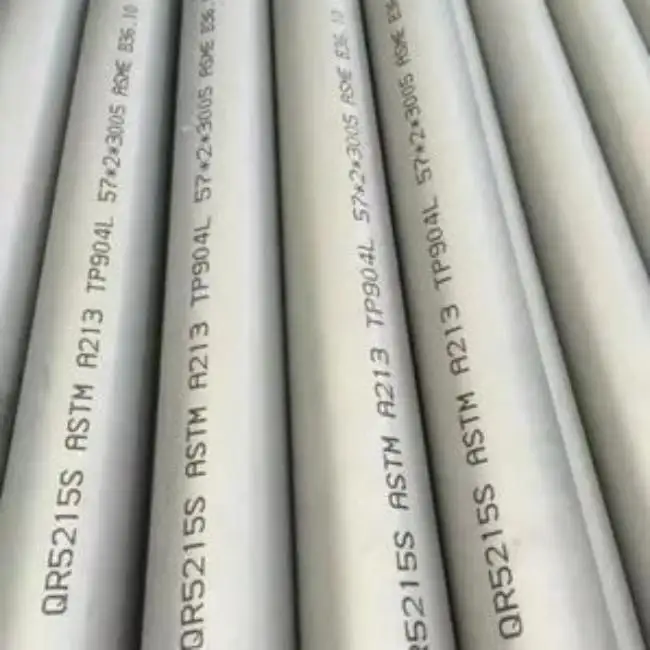

welded and drawn stainless steel tubing

Welded and drawn stainless steel tubing represents a sophisticated manufacturing process that combines the efficiency of welding with the precision of drawing operations. This specialized tubing begins as flat stainless steel strip that is formed and welded into a tubular shape, then subjected to a drawing process that enhances its mechanical properties and surface finish. The manufacturing process ensures exceptional dimensional accuracy, superior surface quality, and remarkable mechanical strength. These tubes feature consistent wall thickness, excellent roundness, and precise diameter control, making them ideal for applications requiring high performance and reliability. The welding process creates a strong seam that, after drawing, becomes nearly indistinguishable from the parent material. The drawing operation not only improves the tube's dimensional accuracy but also increases its strength and creates a smoother surface finish. These characteristics make welded and drawn stainless steel tubing particularly suitable for industries such as aerospace, automotive, medical devices, and chemical processing, where precision and material integrity are paramount. The tubing's corrosion resistance, combined with its mechanical properties, ensures long-term reliability in demanding environments.