5 sch 10 stainless pipe

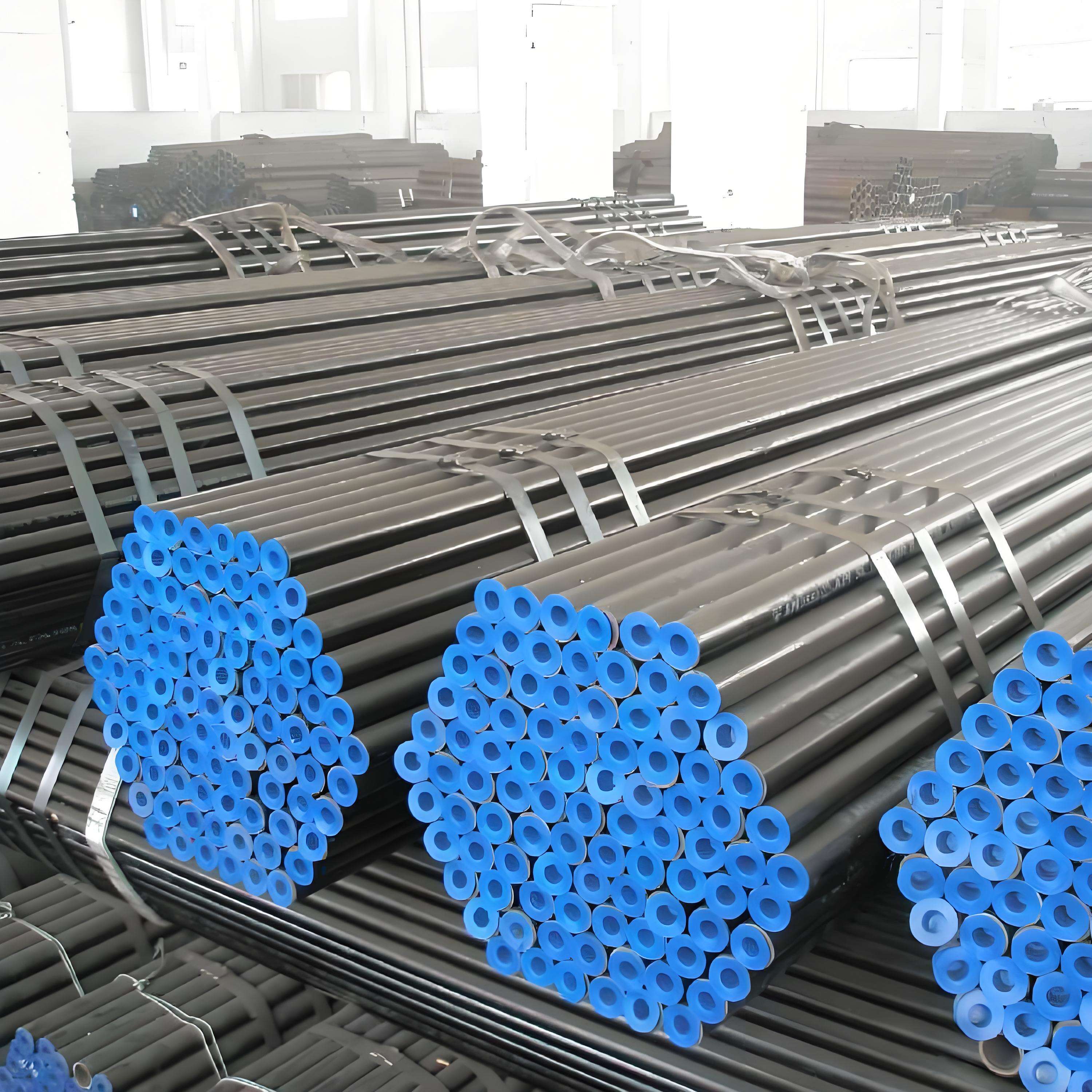

The 5 schedule 10 stainless pipe represents a crucial component in modern industrial applications, characterized by its precise dimensional specifications and superior corrosion resistance. This particular pipe configuration features a nominal outside diameter of 5 inches with schedule 10 wall thickness, providing an optimal balance between strength and weight efficiency. Manufactured from high-grade stainless steel, these pipes demonstrate exceptional durability in various operating conditions, including extreme temperatures and corrosive environments. The schedule 10 designation indicates a specific wall thickness that makes it particularly suitable for low-pressure applications while maintaining structural integrity. These pipes are extensively utilized in process piping systems, chemical transfer operations, and various industrial fluid handling applications. The material composition ensures excellent resistance to oxidation and chemical degradation, while the standardized dimensions facilitate seamless integration with existing piping systems and components. The manufacturing process adheres to strict quality control measures, resulting in consistent product performance and reliability across various applications.