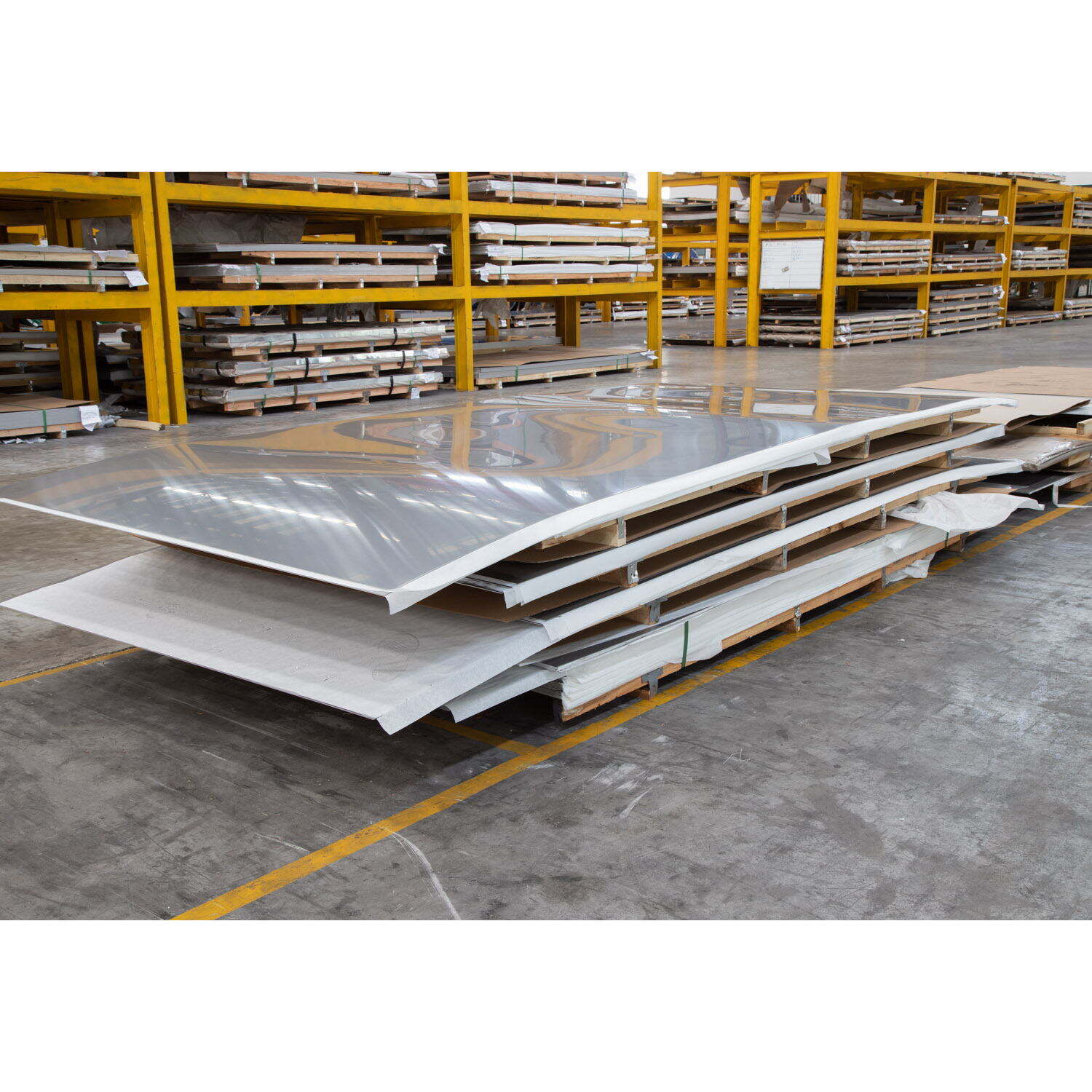

316l stainless steel plate

316L stainless steel plate represents a premium grade austenitic stainless steel material known for its exceptional corrosion resistance and durability. This versatile plate features a low carbon content, typically below 0.03%, which significantly reduces the risk of carbide precipitation and enhances its resistance to intergranular corrosion. The addition of molybdenum in its composition provides superior protection against pitting and crevice corrosion, particularly in chloride-rich environments. The plate maintains excellent mechanical properties across a wide temperature range, from cryogenic conditions to elevated temperatures up to 870°C. Its non-magnetic properties and outstanding weldability make it ideal for various fabrication processes. The material exhibits remarkable resistance to numerous chemical compounds, including sulfuric acid, phosphoric acid, and other aggressive media. These plates are manufactured to strict international standards, ensuring consistent quality and performance across applications ranging from chemical processing equipment to pharmaceutical manufacturing facilities. The surface finish options available include mill finish, polished, or custom treatments to meet specific requirements.