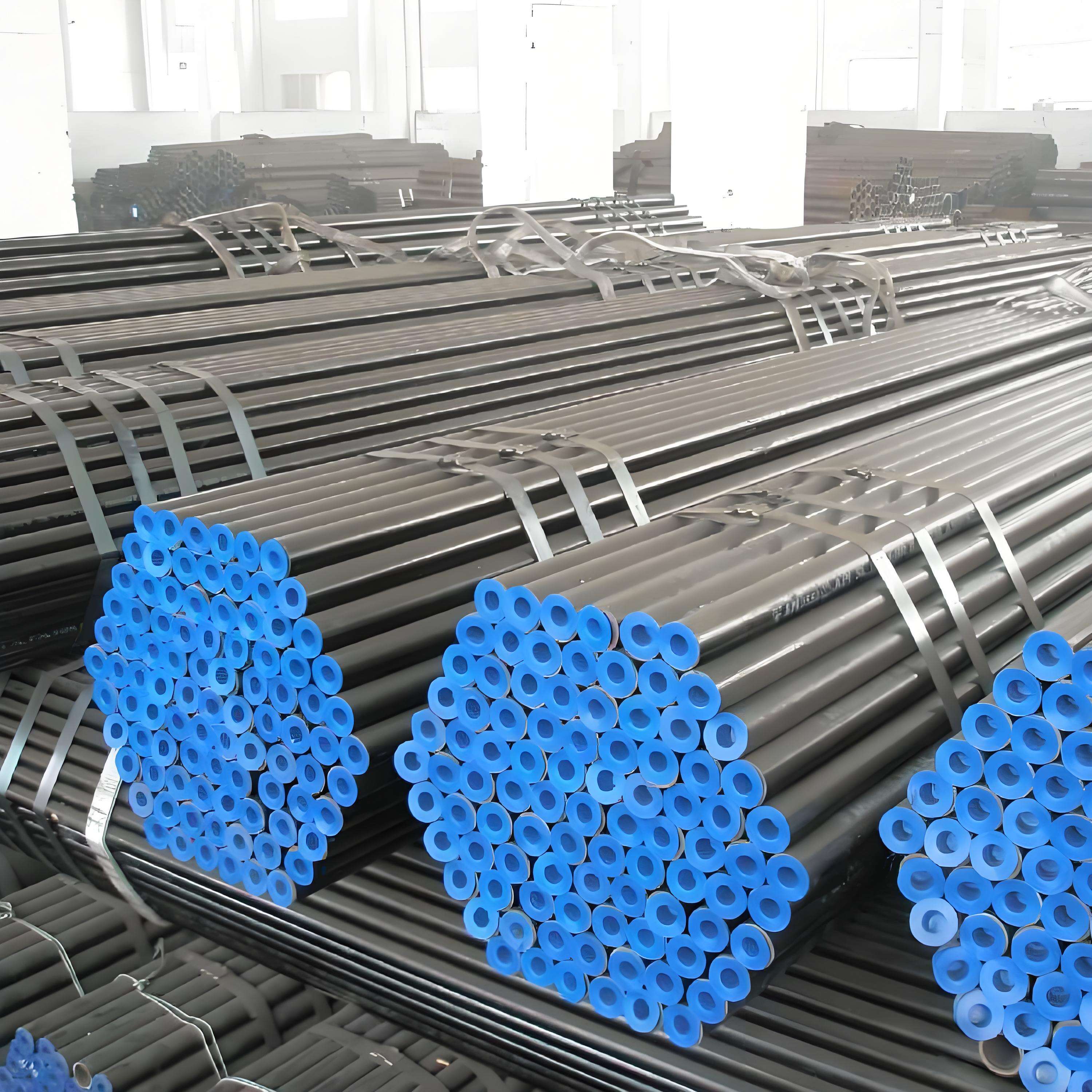

17 4 seamless tubing for sale

17 4 seamless tubing represents a premium grade stainless steel solution engineered for superior performance in demanding applications. This specialized tubing is manufactured through an advanced seamless process, ensuring uniform wall thickness and exceptional structural integrity throughout its length. The 17 4 designation refers to its unique composition of approximately 17% chromium and 4% nickel, creating a precipitation hardening stainless steel that delivers outstanding mechanical properties. The tubing exhibits remarkable corrosion resistance, high strength to weight ratio, and excellent temperature performance ranging from cryogenic to elevated temperatures. Available in various dimensions and lengths, this tubing is precision manufactured to meet stringent industry specifications and quality standards. The seamless construction eliminates potential weak points associated with welded tubes, making it ideal for critical applications in aerospace, oil and gas, chemical processing, and medical industries. The material's ability to maintain its mechanical properties while resisting stress corrosion cracking makes it particularly valuable in high pressure and corrosive environments.