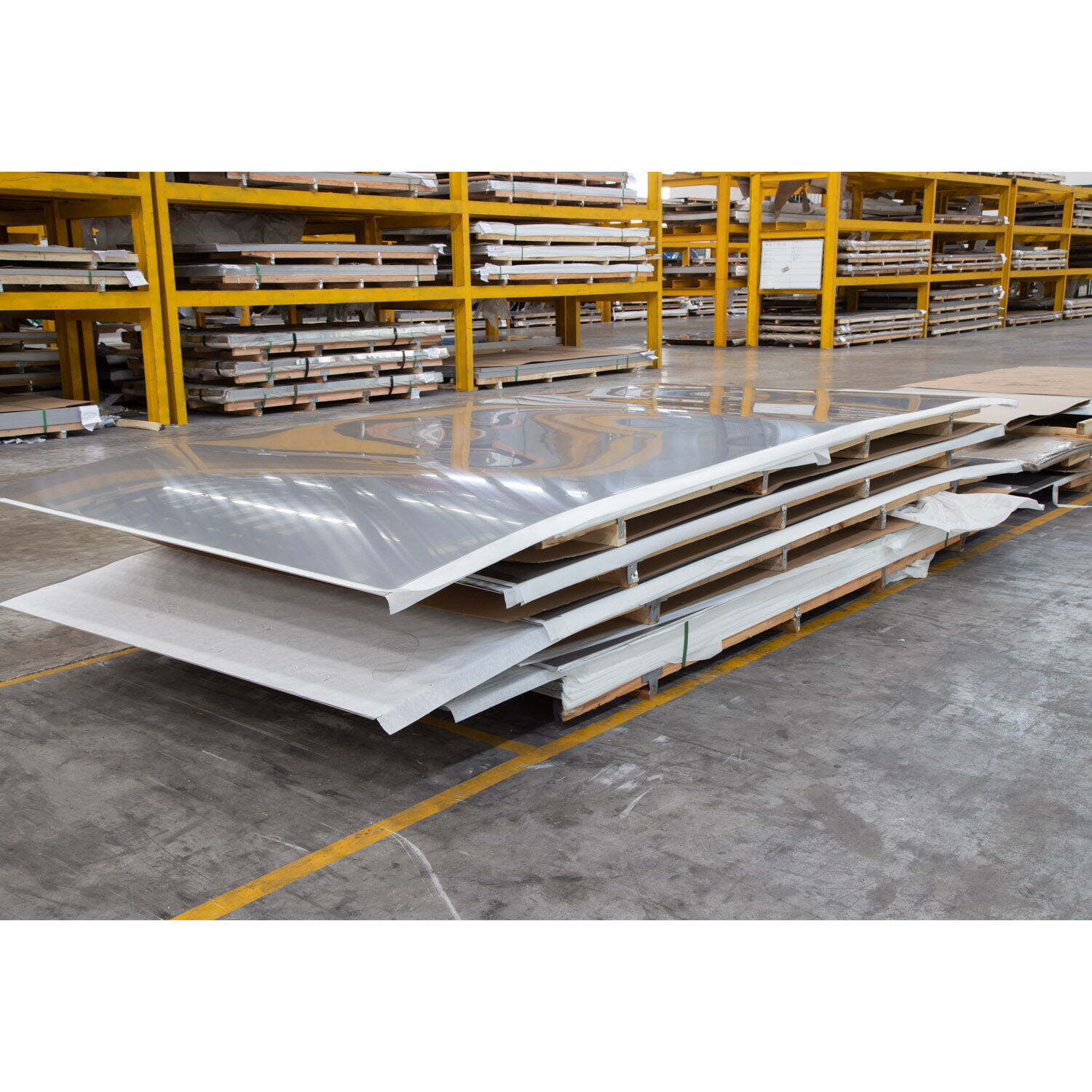

seamless ss

The seamless ss represents a groundbreaking advancement in stainless steel technology, offering unparalleled performance and versatility in various applications. This innovative material features a continuous, uninterrupted surface structure that eliminates traditional weak points and potential failure areas. The manufacturing process involves a sophisticated combination of heat treatment and precise metallurgical control, resulting in a product that maintains consistent properties throughout its entire composition. The seamless ss exhibits exceptional resistance to corrosion, temperature fluctuations, and mechanical stress, making it ideal for demanding industrial applications. Its uniform structure ensures superior strength and durability while maintaining excellent formability and weldability. The material's smooth surface finish not only enhances its aesthetic appeal but also contributes to improved hygiene and easier maintenance. In critical applications such as chemical processing, pharmaceutical manufacturing, and food production, the seamless ss provides essential contamination prevention and reliable performance. The material's unique properties allow it to maintain structural integrity under extreme conditions, making it a preferred choice for high-pressure systems and safety-critical components.