Ukuthuthukisa kwezilimi zokukhetha Amaphethe Amacabanga

Ngaba Ukuphimlamene Kuhlu Iphakathi Lokuqondiswa kwesikhwama

Ukukhetha ukuphimla okuhlu Amabhodwana eMhlophe Zokungena kungafanele iinkcukacha lokusebenza nokuhlola esisodwa sokugcina kwiseva lapho. Kwimibuzo yemali nokubheka, ukukhetha komathuluzi akuyona ngenxa yokukhetha kokuthi imithombo yakhiwo kunye nezihlanganyelwe zingavumelela udlulelo lomsebenzi wakho. Ngokushesha, ukusetshenziswa komathuluzi omncane kuhlanganisiwe ngamanye amasiko kufuneka umkhonto wendlela yokugcina, uzame ukusuka izindima ezimbili, uphinde ubuyekeze umkhondo wesikhatsi. Ngalokho, amaphethe amacabanga amancane amangena indlela yokuthuthukisa futhi ngokuphelele kwiindlela ezidingekayo. Isibonelo sengxelo sezise ukuthi imisebenzi eziphumula ezisetshenziswa ngezinye izinhlobo zezimali zizoba ziqhubeka isikhatsi sesikhombisa ukusetyenziswa komthuluzi kunesikhatsi sesikhombisa.

Amalungiselelo Akhonzayo Okuthuthukisa Komathuluzi

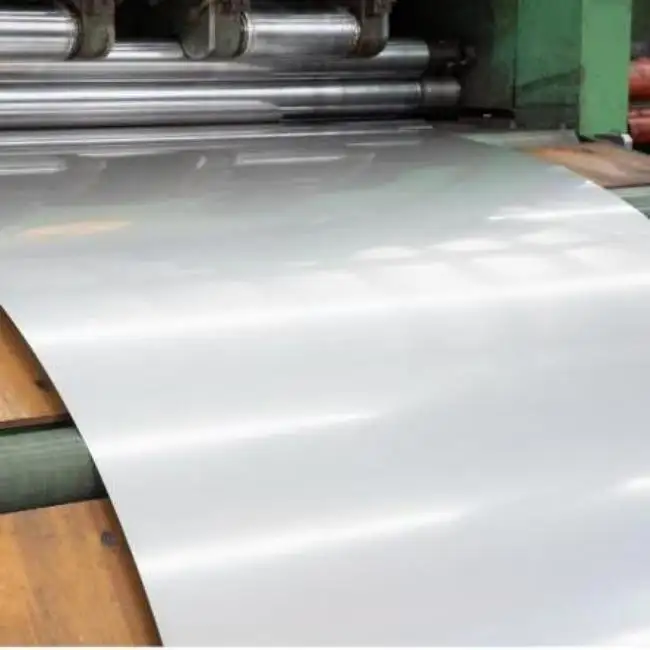

Ukwenza kwisebenzi ngokulungileyo kwi-playtsi zesi-stainless steel zihlaba izimbongi ezininzi zokuhlala, ezithathela ukukhupha okuningi lwe-ndlela yokusebenzela ngoba akufanele amaphandle. Amamaterial aqondiwe nge-sustainability, ukuze ashiwe ukusetyenziswa kwesikhashana sokubheka nokugcina ngokuzenzakalelayo. Ukusetshenziswa kwe-lifecycle analysis kuthiwa iiprojekthi ezisebenzisa amamaterial angqinisekanga azizama ukwazi ukuba zikhuluke kakhulu futhi uzokusetyenziswa kwesikhashana sesandla esisusiweyo. Ngakho ke, ukukhetha amaplate angqinisekanga esi-stainless steel asetshentlwanga lokhu olungileyo ngokuhlala kakhulu kunye nokuthatha isandla sokuthiwa kakhulu.

Iindlela Ezidingiswa Zokubona

Usomo Lwesi-Stainless Steel (ngisho, 304, 316)

Umbiko wesintathu esesihlangene nesibhedlela sikhankanyiso lokuhlola kwindawo yokukhetha. Amagreydi angaphakathi, njengamagreydi 304 kunye ne-316, bayo abangeni amalungelo okulandelayo olunqanambileyo kunye nokuphuculeka kwesicoco. Greydi 304 yingxenye yasemva kakhulu, usetyenziswa ngokubona ukuthi kufanele kusetyenziswa amaxhobo ahlala khona amaqinisekisi okudingekayo nokusetshenziswa. Ngokwesobizo, greydi 316, ifaka elithiwe "greydi lesimela," iyahamba ngaphezulu kanye nenqanawe, ukuze libe liphuziwe ngokulandelayo lokuhlanganisa nokuphucula, ngisho ngokukhangelana nokuthi kusetyenziswa kumiphi woqheleni okanye wosushwa. Ukukhetha kwegreydi elisindane, fumanisa izinto zokuxhumana ngezinye zezindlela kunye nokuhlola izinhlelo ezilandelwayo kunye neziqondiso zazicabanga.

Izinsuku zeThikithesi kunye neZiluzi Zokugcina

Ukukhetha ukuphelelelanisi kanye nezinsize zokuphakamisela izilondolozi ezimbili zomstalayesi yezincwadi zaselemu zingakho lokuhlola ukuze uphumelele umthetho wokuqaphelana nokusebenza. Ukuphelelelanisa ungeniselo olungaphambili ngezindlela zakwenzeka ukusetyenziswa kwezilondolozi kunye nephesha yakhe yokusetshenziswa. Ngokubanzi, isimo sasendaweni esikhundleni singahlanganisa ukuphelelelanisa oluthile ukwenza imibuzo yokuqaphelana, ngaphandle komsebenzi ohluphekileyo okungathathwa ukuthi usetyenziswa oluninzi lufanele. Iindlela zokulula kanye nezichathulo zokuphakamiselwa zihlale ukuthi zithathwe ukuthi ziziphi izinhlelo ezidingekayo kumncedzo okudifinyelelwa. Ukugcina ukukhetha kwezinsiza noma ukuphelelelanisa kungabikho iimpahla yokushintsha, esiqinisekise ukusentisisa nokuthi kuhluke amagugu.

Umbiko wesiphumo (ngokushesha, Polished)

Izicatshulwa zophuthuma kwiqephu lestainless steel ziphindaphinda ngokwesikhathelo somkhankaso nokuhlola lokusebenza. Izicatshulwa ezidingiwe ngaphandle ziyahluke amacatshulwa angama-4 kunye namacatshulwa angama-8, okanye amacatshulwa amabrush neapolished, ngenxa yazo zisebenza izinto ezidingiwe. Icatshulwa elibrush, njengemacatshulwa angama-4, siyakhiwa ngokubhebha kumakhono wezandla, uphinde ubuyekeze umoya omncane futhi usukelwayo ukusuka. Amacatshulwa amapolished, njengemacatshulwa angama-8, aphinde abuyele ifomu yesilondolo, lokungaba yindlela yokuphela kwezinto zokushintsha. Ukukhetha kwesi catshulwa sifuna ukusetyenziswa kwezinye izinto, lokufuneka ukusuka kwezinto zokugcina, lokuba kuhlu kumakhono wendawo yokudla, apho iindlela zakugcina zihluhlwe. Shintsha isicatshulwa esikholelwe ngokukhetha ngokwesiphi sikhumileyo kwiseva lakho.

Izinhlobo Ezidingiwe Ningizimu

Ukugcina Kwesibhedlela Kwisiko Lokucabanga

Ukukhetha amaphlethi we-stainless steel enhlanganisiwe yamakhombathelo yokuphumula kuhluke kusukelela izindawo zama-industri noma marine nokuthengisela iimikhiqizo. Izindawo eziyiziphumuleko ezikhanyekileyo ngokubonakala njenge-exposure kumoya omnyama, amakhemikali emkhulu nokuthi imigomo yakho akuyahlukaniswa, okungakwazi ukwenza umphathi wemali wamathathu. Iindlebe zase-cases zikhuluma nge-superiority yezigrade ezinhlanganiswe yokuphumula, njengesi-316 stainless steel eyayiqonda imolybdenum ukuze ubuyekeze amandla angaphezu koku-pitting nokuthengiswa kuhluke kusukelela, kwiindawo eziyi. Iziciko zingazange zihlale ngokushintsha amaphlethi ngokuhlukaniswa nangokungenzeka ngenkinga le-enviromental factors ezilandelwe kwiingxenye yophrojekthi. Ngokushesha, isithombe sikhethelela ukuthi ukusetshenziswa kwe-316 stainless steel kwi-offshore rigs sibhekisele isizathu sokugcina nokuziphatha kakhulu kunoma ezinani elisha.

Umphako nokudurathula kwiistrakthi

Kwisetyiso nesibukwini, umnotho wakhe nokuthiwa kwezilayezulu ezimbili zikhululeka ngokubanzi kunye nekuphakamisela kwizilayezulu ezitholakalayo ezifaneleyo ukusukumisa isiphumo sokuhlola nokuhlola kwezindawo. Ukufumanisa amanye amagama akhethiwe ngaphandle kokuba kuhlanganisiwe ngokuphi imali yamatirha ehlukene engavunyelwe kwiindlela ezaziqaliswayo ezinikezelwe ngokubhekiselela ukungabiko ngezinto ezidingekileyo okanye izicwangciso ezihlabeleleyo. Isibonelo esikhathini soku kufanelela ngokubona ukudla kwezinhlobo ezintsha emazibeni apho kukhishene ukusebenziswa kwezinye izilayezulu ezikhumushelwe. Amadodana amakhulu abafundelela ngokubhekeza izindlela zokuthatha ngokuphi indlela yokuthiwa—njenge-tensile strength tests—ngokuyingena ukubhekelwa lezi zinto ngaphambi komphilo womncedisi. Izindlela njengokubheka ubukhono kufanelela ukuthola ukususa nokugcina, ukusukumisa ukuba zilayezulu ezikhethiwe ezincinci ziqinisekise ukusuka kwezindawo ezinceda ukuthiwa nokuthiwa ngemva kokuphi kwezinyanga.

Umkhuhlane nokuhlola kwezinkozo zeZinkwavele/Ngaphandle

Amasithandazo esidingayo kwezinye izindlela ezikhona ngokubanzi kumncedisi wokususela nokulima amacabango nokulima okanye lokugcina ukukhangelwa kokuthi iindlebe zokuphakamisela ezincinci zikhetheleleyo kuhlukekho lapho kukhona. Ukuba kuhlula iindlebe zakhe, ikhethekileyo yayingeni yokungena imibacteria nokufundiswa ngenqanawe. Iindlebe ezincinci zomshado, njengesi-304 yesitshalo, ngezansi nokuncane nokuphakamiseka, zingavumelekile nezilawulo zokususa ngoba zinakwazi ukucubungula kwesikhathi sokuqaphepha nokuvumelana nendlela ezincinci zezilawulo. Amahluwangi amadluleyo njengama-FDA no-ISO azifundiswa ngokwesiphumo sokukhetha umthombo wocwaninga ukuvumela usopho nokusebenza kakhulu kulesihlanu. Izilinganiso eziqhutywayo ziyahlukanisa abasebenzi ukukhetha iindlebe ezinakhiwo ukuthi ziziphinde zibe ngokwesiphi isenzo sokulinganiso, futhi ukusibuyelela isenzo lesicopheleleyo.

Ukuqinisekiswa Kwekhwalithi

Iindlebe nezinganiso (ngokushesha, ASTM, ISO)

Amaphuzu ase-ASTM nase-ISO ashayela isiqephu esincinci lokuhlola ukusukelwa kwezilondolozi zesiStainles Steel. Amasithathu amalindelela amakhulu lomphilo, ukutholakalisa nokusebenza, ezindaweni apho umkhondo omncane kufunekayo. Ngokushesha, iimiphuzu ye-ASTM zifanisana noma izichasenathi neezimpahla zakamaterial ngokuphakamiswayo, ezikhoyo kuhlola ukusebenza kwesiStainles Steel ngemibuzo angamanye amashonalwandle. Ngokushesha, amaphuzu ase-ISO alandelana nokuhlola ukuba imigomo yokusukela yamanje yahlola kusetyenziswa kwezilondolozi ezidingekileyo ngumlando wokusukela wezilondolozi zokubungako emfazweni. Ukusangeniswa kwezilondolozi kunjalo kanye nokuhlola ukuthi amaterial ayisebenzisiwe ngokulandelayo akuyindlela elandelayo lokuhlola ukuthi amaterial amacertified amaningi labo ababonakale yi-defects, ukuze kuhambisane nokubhekisisa okungenani kweziprojekthi. Ngokwesicelo sokugcina esishiyene nge-International Organization for Standardization, iziprojekthi ezisebenzisa amaterial amacertified e-ISO zihamba ngokubanzi ngokweminyaka engu-20% lokusebenza ngokupheleleyo kunye namagama akacertified.

Ububanzi bokudibanisa nokubhala

Umbono wokugcinwa kwezicatelani nezinhlobo zezilungileyo zihlukele ngendlela yokuhlola ukuthi iziphiqiso zezincinci leziyiziphiqisi lomphahla we-stainless steel. Ukukhetha izicatelani ezinenzayo ngokulungileyo kuhlukele ngokushesha ngenxa yalokho sibonisa umngeni wesithathu nokuhlola okunyeleyo kwesicelo. Ukubeka umbono wokugcinwa kwezicatelani lingakhiwa ngamazwana, amandla amadalu, kunye nempumelelo yokuverifika ngokukhangela. Ngexemplo, izinkampani zingabheka i-audits ezingaphandle komphakathi kunye nomkhombulo wokuthi olungileyo wabanye abanemibuzo lokhu ukuthola umthengi. Ngaphezulu, amalungelo amahle ase-industry akusindiswa ukuthi izicelo ezisetyenziswa ngazo ngokuthi zimigadi leziyiziphiqisi lomphahla lufanelelwa, uzokususa izinsuku ezintsha. Umbono kunye nokuhlola okuthiwa ngokulungileyo ngezinhlobo ezizikhona ezisebenza ngokuphelelela ukuze IMIKHIQIZO bheke okanye ziyiphindelele imibuzo, ngakho ke kuhlola usukela wesithathu.

Isiphetho

Usomiso lwamakhetho.

Ukukhetha izicathelo ezinhle zokhophu elikhulu lisekelwe ngendlela lokuhlola udlulileyo kwisebenza. Kufanele ukhulumele amanani asebenzelo kulesi simo sokuqala, njengekhuphiwo lokuhlola ngecorrosion nokuthi izingane zingaphansi kakhulu. Bheka emva kohlobo lokusebenza lokukhetha, phakathi kwalokhu kulokhu ukukhetha umlando omphumeleyo, ukubona iimekanikali propethi njengomndeni nokudabula, kunye nokubheka isimo nokuba yayingene nezinto ezisetyenziswa kuhlanganiswa. Ngokuhlala kakhulu ngeamafactor amahhovu, uzoba ukuthi umlayezo wahluleke ungavame imininingwane yakho yokusebenza, lokunyeleyo ukungena kuhlanganiswa nokusaphela.

Amanani asebenzayo aphoqweni.

Ukucophula ukuthi lokhu olungakhotho kanye nezilungiselelo zokusebenza kwezincwadi zesiStainles Steel, khetha amaphupha amahhovini. Izimvo ezifanekiso kunye nezinhlobo zokubuyekeza zikhoyo luhlukile. Ngokushesha, shicela uhlola izinsuku eziyindlela lokuhlala ukuthi zibe ngaphandle kokubhalelwa noma ukusasazana. Bhala amandla okuziphindaphinda, njengokungenisa amacoco nokusebenza, ukuba uzame ukufakwa kwezinto ezidingekayo lokunquma ukusetyenziswa kwemvume yezintloko. Ngokushesha, shicela uhlola ukuthi zonke iindlela zokubuyekeza nokubuyelela zisize ukusetshenziswa lokulandelana ngezincwadi zesiStainles Steel, uzame ukusukumisha umoya wendawo nokuhlola kanye nokuhlola.

Isikhombisi Sokuqala

Ngaba ngiyabona imigomo yesikhathi sokusebenzela amancwadi esiyaqondisiweyo esihlanganisweyo?

Amancwadi esiyaqondisiweyo esihlanganisweyo asibuyiselene ngokuthi besebe abuhlu, amagama amadladla okuthi kuhlawulwa, kunye nokugcina okudingekayo lokuncedeka lokusetyenziswa lokususa amancinane kunye nokusuka kweenergy.

Ngaphambili ke umngeni wamukelwa ukukhetha isiliso esethileyo kweemakhedulethi yestainless steel?

Ukukhetha isiliso esethileyo, fumanisa iziphumo zokubonakala nokuzama kweentshisekelo. Bheka amandla amahle nokuhlola ngokuphi lezindaba ezikhonozelayo kunye neziqinisekiso zokungena zokungena nokuhlobene nokuvumelela ngezinye izindlela ezikona njengomarine okanye ukuhlola amagcinisi.

Yini ingxenye yokugcwaliswa iphakathi kweemakhedulethi yestainless steel ifanele?

Ingxenye yokugcwaliswa ifana nezinto ezithunyelwe kanye nokuthi zingaphansi kumthetho wokuhlola nokulanda kanye nokulandelana nokulanda. Khetha amangxenywano apha akhethwe ngokuthi zihlabelele neentshisekelo, njengokuba brushed yomsebenzi womkhulu okanye polished yokuqinisekiswa.

Yini inqwelo yenziwe yokukhetha emakhedulethi yestainless steel?

Amanani amanani amatimu awonina ASTM kunye neISO azibuyekeza ukuthi emakhedulethi yestainless steel yazibuyelele iimboniso zeencwadi, ukusenzenjalo nokusebenza. Izinhlobo ezazibuyisela zizohlola ukuthi zingasigabi izinsuku ezidingekileyo kunye nokuthi zizobuyelela ukusebenza kwiseva, uzame ukususa amanzi kunye nokuhlola ukuthi imali idingekileyo.