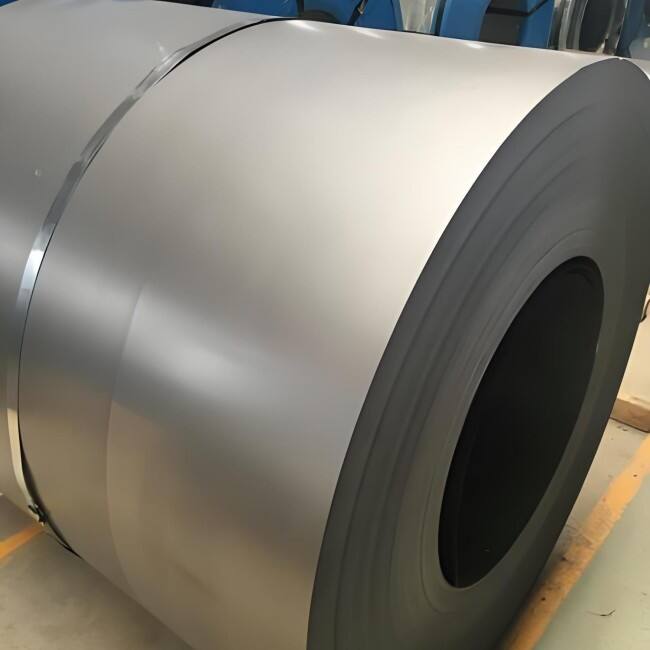

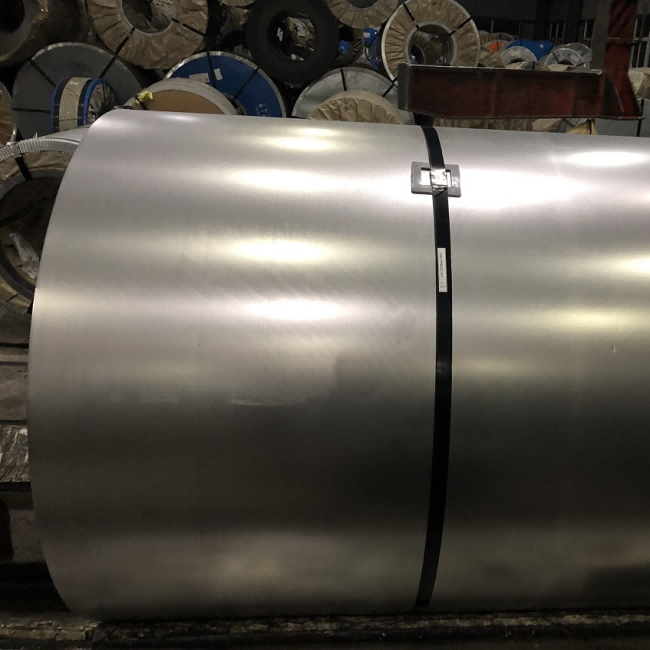

SPCF Cold Rolled Carbon Steel Coil

Carbon steel coil is a common steel products, mainly made of carbon steel (carbon content is usually between 0.05% ~ 2.0%) by hot or cold rolling process, in the form of coils.

- Overview

- Recommended Products

Main features

1.Ingredients: Iron and carbon as the main elements, with a small amount of silicon, manganese, phosphorus, sulfur and other impurities. According to the carbon content is divided into:

①low carbon steel coil (C ≤ 0.25%): good plasticity, easy to process, commonly used in stamping, welding.

②Medium carbon steel coil (0.25% < C ≤ 0.6%): high strength, suitable for mechanical parts.

③High carbon steel coil (C>0.6%): high hardness, wear-resistant, but brittle, mostly used for tools, springs.

2.Surface treatment: it can be divided into hot rolled coil (with oxide skin on the surface), cold rolled coil (with smooth surface), galvanised coil and colour coated coil.

3.Specifications: the thickness is usually 0.2 ~ 25mm, the width can be up to 2000mm or more, the coil weight can be tens of tonnes.

production process

1.hot rolled carbon steel coil: billet heated to high temperature and rolled, low cost but rough surface, commonly used in structural parts.

2.Cold rolled carbon steel coils: hot rolled coils are formed after pickling and cold rolling, with high dimensional accuracy and smooth surface, used for precision processing.

3.Subsequent treatment: can be galvanised, painted or coated to enhance corrosion resistance.

Application fields

1.Construction industry: steel structure, roofing, bridges (hot rolled coils mainly).

2.Automobile manufacturing: body panels, chassis parts (cold rolled coils or galvanised coils).

3.home appliances: refrigerator, washing machine shell (galvanised or colour coated coil).

4.Mechanical processing: bearings, gears (medium and high carbon steel coils).

5.Pipes and vessels: welded pipes, storage tanks (hot rolled coils of greater thickness).

Advantages and limitations

1.Advantages:

Low cost, moderate strength, good processability.

Properties can be adjusted by heat treatment (e.g. quenching, tempering).

2.Disadvantages:

Prone to rust (requires surface protection).

Poor weldability of high carbon steels, cold embrittlement is evident.

Markets and Standards

1.Common grades:

①China: Q195, Q235 (low carbon); 45# (medium carbon); 65Mn (high carbon).

②International: ASTM A36, JIS G3131 (SPHC), EN DC01.

2.Purchasing Note: You need to specify the thickness tolerance, roll width, inner diameter (usually 508mm or 610mm) and surface quality requirements.

Comparison with other steel

1.vs stainless steel coils: carbon steel coils are cheaper but not corrosion resistant.

2.vs Alloy Steel Coils: Carbon steel coils are usually lower in strength but easier to process.

Carbon steel coils are one of the most used steels in industry due to their cost effectiveness and versatility, and the choice of carbon content, process and surface finish needs to be weighed against the application.