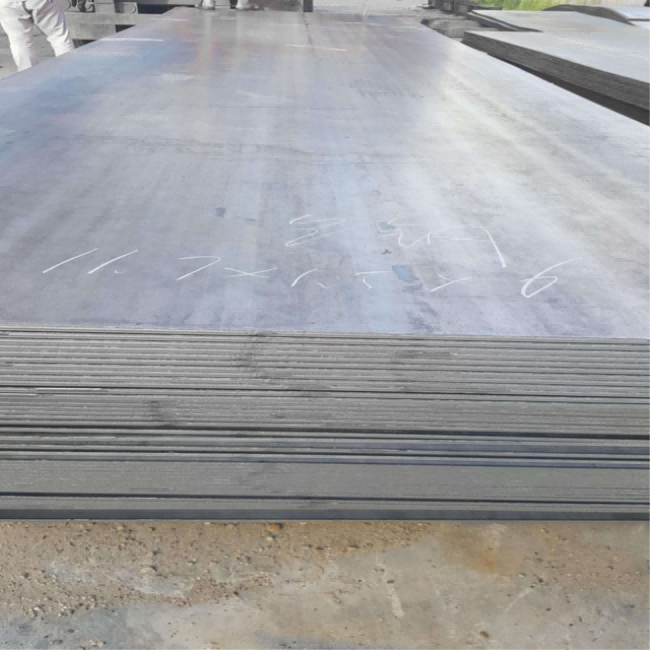

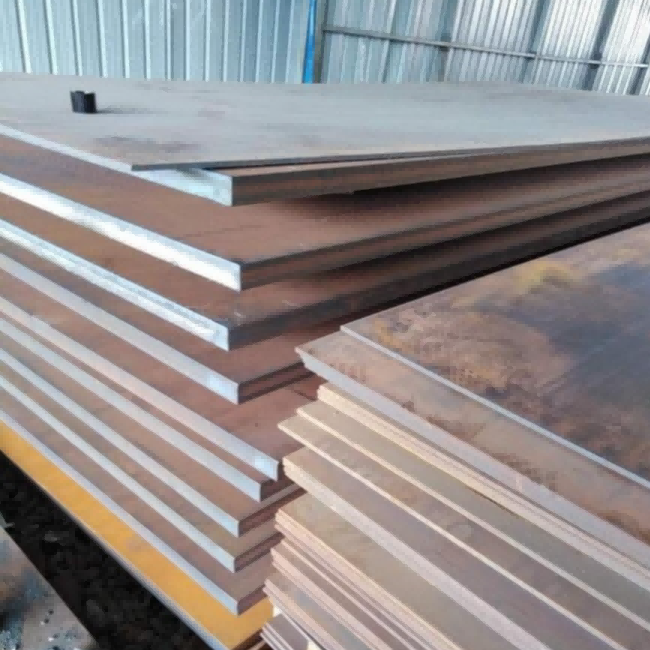

S45C Hot Rolled Carbon Steel Sheet

Carbon steel plate is a type of steel plate with carbon as the main alloying element, its carbon content is usually between 0.05% and 2.0%, and it is one of the most commonly used types of steel in industrial production.

- Overview

- Recommended Products

Main Composition and Classification

1.Low-carbon steel plate (C≤0.25%)

Soft, easy to process, good welding performance, commonly used in stamping parts, car body, building structure, etc..

For example: Q235 (Chinese standard), A36 (American ASTM standard).

2.Medium Carbon Steel Plate (0.25%

Higher strength, combined with some toughness, need heat treatment (e.g. quenching, tempering) to optimise performance, used for mechanical parts, gears, shafts, etc.

Examples: 45# steel (Chinese standard), 1045 (American standard).

3.High carbon steel plate (C>0.6%)

High hardness but brittle, mostly used for tools, springs, cutting tools and other wear parts.

For example: T8, T10 (tool steel).

Manufacturing process

1.Hot rolled carbon steel plate: rolled at high temperature with oxide skin on the surface, thickness usually >1.5mm, low cost, used for structural parts.

2.Cold Rolled Carbon Steel Plate: rolled at room temperature, with smooth surface, accurate size and thin thickness (0.2~4mm), used for precision instruments, home appliances, etc.

3.Galvanised/coated sheet: galvanised or coated with an anti-corrosion layer on the surface of carbon steel sheet to prolong its service life (e.g. galvanised sheet for roofing, piping).

Core Performance Characteristics

1.Advantages:

High strength, inexpensive, easy to process (cutting, welding, bending).

Properties can be adjusted by heat treatment (e.g. quenching to improve hardness, annealing to improve plasticity).

2.Disadvantages:

Poor corrosion resistance, need to be protected by paint or plating (compare stainless steel).

Decreased toughness at low temperatures (high carbon steel is easily brittle).

Typical fields of Application

1.Construction industry: steel frames, bridges, reinforcing bars.

2.Manufacturing industry: automobile chassis, pressure vessels, machinery and equipment frame.

3.Daily necessities: hardware tools, furniture skeleton, shelves.

4.Energy and transport: ship decks, railway tracks, oil pipelines.

Common standards and grades

1.China: Q195, Q235, Q345 (GB/T 700, GB/T 1591).

2.USA: A36, A516 (ASTM).

3.Europe: S235JR, S355JR (EN 10025).

4.Japan: SS400 (JIS G3101).

Selection considerations

1.Environment: wet or corrosive environment need to choose galvanised sheet or change to stainless steel.

2.Processing needs: Welding priority to choose low carbon steel; high hardness needs to choose high carbon steel and heat treatment.

3.Cost: Carbon steel is less expensive than alloy steel or stainless steel, suitable for projects with limited budget.