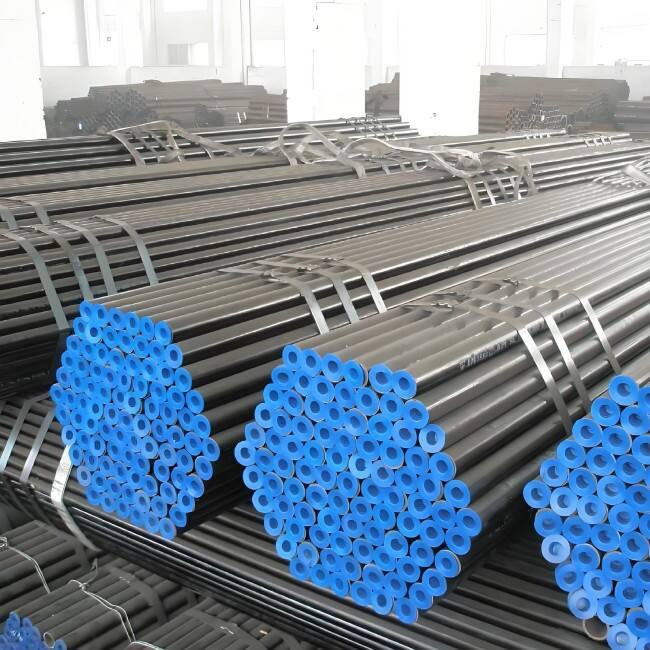

Q235B Carbon Steel Pipe

Carbon steel pipe is a kind of steel pipe made of carbon steel as the main material, which is widely used in the fields of industry, construction, energy, etc.

- Overview

- Recommended Products

Basic concepts of carbon steel pipe

1.Definition: Carbon steel pipe is a steel pipe with iron and carbon as the main components (carbon content is usually less than 2.06 per cent), and may contain small amounts of manganese, silicon, sulphur, phosphorus and other elements.

2.Characteristics: high strength, good toughness, low cost, easy to process and weld, but poor corrosion resistance (need anti-corrosion treatment).

Classification of Carbon Steel Pipe

1.According to the manufacturing process

①Seamless Carbon Steel Pipe

Made by hot rolling or cold drawing process, without welding seam.

Advantages: strong pressure capacity, suitable for high-pressure, high-temperature environment (such as boilers, petrochemical equipment).

Disadvantages: higher cost.

②Welded Carbon Steel Pipe

Made from rolled and welded steel plate or steel strip (common process: straight seam welding, spiral welding).

Advantages: high production efficiency, low cost.

Disadvantages: weak pressure-bearing capacity, the weld seam may become a weak point.

2.According to the carbon content

①low carbon steel pipe (C ≤ 0.25%)

such as Q235, A106 Gr.B, good plasticity, easy to weld, used for building structures, water pipes and so on.

②Medium carbon steel pipe (0.25%

such as 45# steel, high strength, used for mechanical parts, shafts.

③High carbon steel pipe (C>0.6%)

High hardness but brittle, commonly used in tools, cutting tools.

Main standards and grades

1.International standards

ASTM A53/A106 (American Standard), API 5L (oil pipeline), EN 10255 (European Standard).

2.Chinese standards

GB/T 8162 (seamless pipe for structure), GB/T 3091 (welded pipe), GB/T 9711 (pipe for oil and gas).

3.Common grades

Q235, 20#, 45#, ASTM A106 Gr.B, API 5L X42-X80 and so on.

Application fields of carbon steel pipe

1.Construction industry: scaffolding, steel structure support.

2.Oil and gas: transmission pipeline, drilling equipment.

3.Machinery manufacturing: shafts, hydraulic cylinder barrels.

4.Energy and power: boiler tube, heat exchanger.

5.Municipal engineering: water supply, drainage, gas pipelines.

Advantages and Disadvantages of Carbon Steel Pipe

1.Advantages:

Low cost, cost-effective;

Good processing performance (can be welded, bending, cutting);

High strength, high load-bearing capacity.

2.Disadvantages:

Easy to corrode (need to be galvanised, painted or lined with plastic);

Decreased toughness in cold environments.