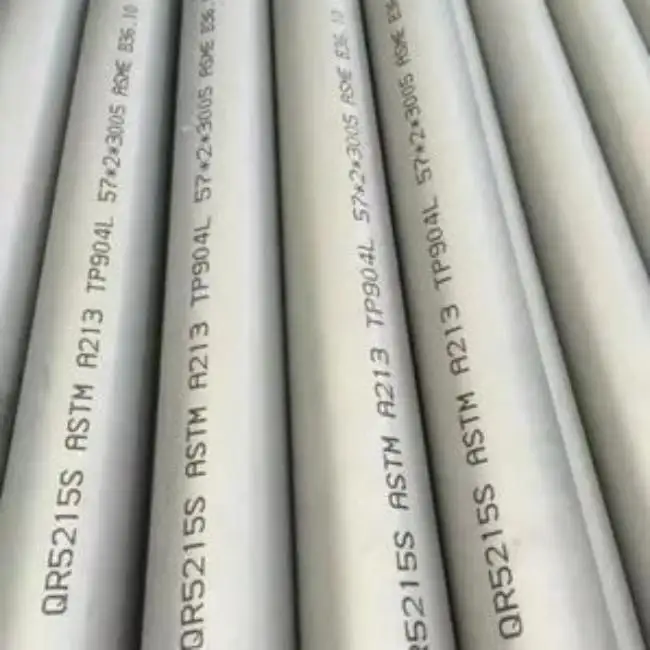

310 stainless steel pipe manufacturer

A 310 stainless steel pipe manufacturer specializes in producing high-quality austenitic stainless steel pipes designed for extreme operating conditions. These manufacturers employ advanced metallurgical processes and state-of-the-art production facilities to create pipes that exhibit exceptional heat and corrosion resistance. The manufacturing process involves careful material selection, precise forming techniques, and rigorous quality control measures to ensure consistent product excellence. These facilities utilize modern equipment for seamless and welded pipe production, incorporating automated systems for cutting, forming, and testing. The manufacturer's expertise extends to customizing pipe specifications, including diameter, wall thickness, and length, according to client requirements. Their production capabilities typically encompass both standard and custom-sized pipes, ranging from small-diameter instrumentation tubes to large-diameter process pipes. The facility's quality management system ensures compliance with international standards such as ASTM, ASME, and DIN specifications. Additionally, these manufacturers maintain comprehensive testing facilities for mechanical properties, chemical composition analysis, and non-destructive examination, guaranteeing product integrity and reliability.