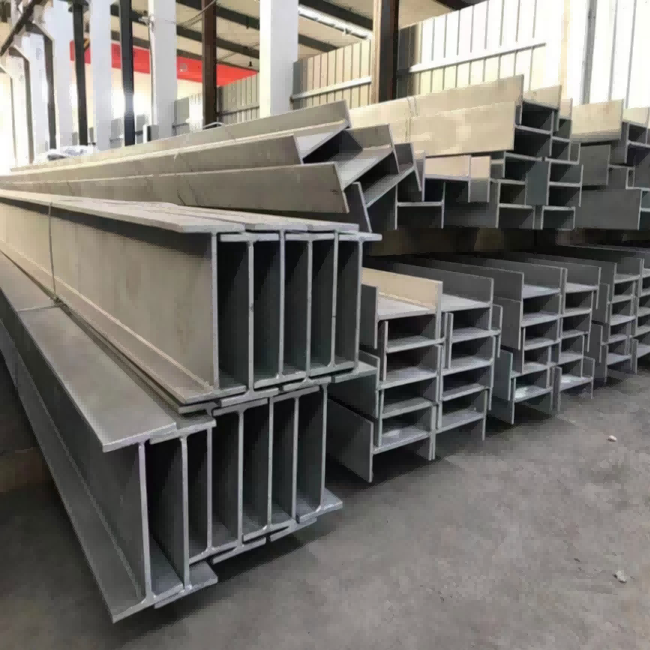

316L Stainless Steel H-beam

Stainless steel H-beam is a stainless steel material (such as 304, 316, 201, etc.) rolled or welded H-sectional steel, both stainless steel corrosion resistance and the structural advantages of H-beam.

- Overview

- Recommended Products

Material Characteristics

1.Corrosion Resistance: Stainless steel makes it suitable for wet, acidic, alkaline or high salt environments (e.g. chemical industry, marine engineering).

2.High strength: compared with ordinary carbon steel H-beam, stainless steel H-beam has high strength but lower weight.

3.Aesthetics: smooth surface, no additional anti-corrosion treatment, suitable for building exposed structures.

4.High/low temperature resistance: some grades (such as 316) can be adapted to extreme temperature environment.

Common materials

1.304 stainless steel: general purpose, good corrosion resistance, cost-effective.

2.316 stainless steel: containing molybdenum, acid and alkali and seawater erosion resistance, suitable for harsh environments.

3.201 stainless steel: economic type, slightly weaker corrosion resistance, suitable for dry environment.

Production process

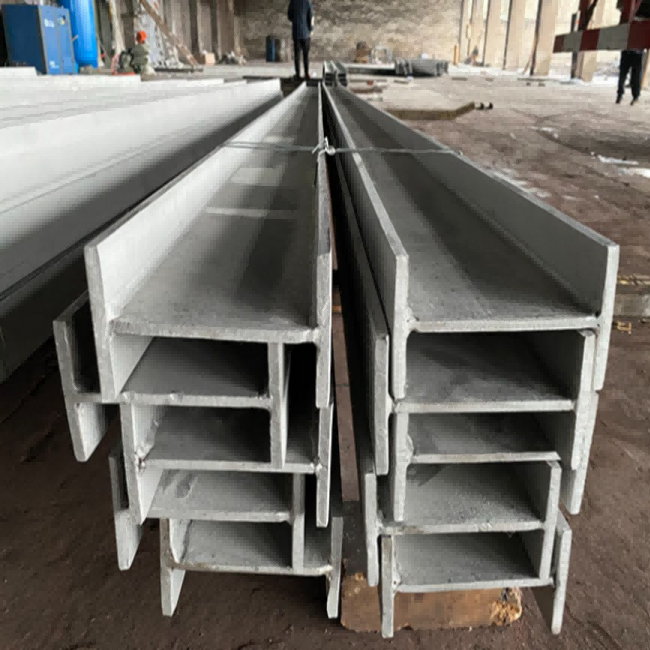

1.Hot roll forming: through high-temperature rolling one-time forming, fixed size specifications, suitable for large quantities of standard parts.

2.Welding: Welded stainless steel sheet, can be customised to non-standard size, but need to control the quality of the weld.

Specification parameters

1.Section size: height (H) × width (B) × web thickness (t1) × flange thickness (t2), such as 100 × 100 × 6 × 8 (mm).

2.Length: usually 6 metres or 12 metres, can also be customised.

3.Standard: refer to GB/T 11263 (China), JIS G3192 (Japan), ASTM A554 (USA), etc.

Application fields

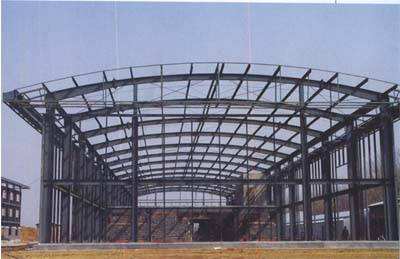

1.Building structures: high-grade curtain wall supports, indoor and outdoor decorative frames (e.g. shopping malls, airports).

2.Chemical/food equipment: corrosion-resistant bracket, conveying pipeline support.

3.Marine engineering: dock facilities, offshore platform components.

4.Environmental protection equipment: sewage treatment plant, exhaust gas treatment tower.

Advantages and disadvantages

1.Advantages: long life, maintenance-free, environmental protection, modern appearance.

2.Disadvantages: Higher cost than carbon steel H-beam (about 3-5 times), difficult to process (need special tools).

Suggestions for selection

1.Environment matching: 316 is preferred for humid or corrosive environments, and 304 is preferred for general environments.

2.Budget control: 201 material can be considered for non-load-bearing decorative purposes.

3.Supplier qualification: need to provide material reports (such as SGS certification) to ensure that the composition of the standard.