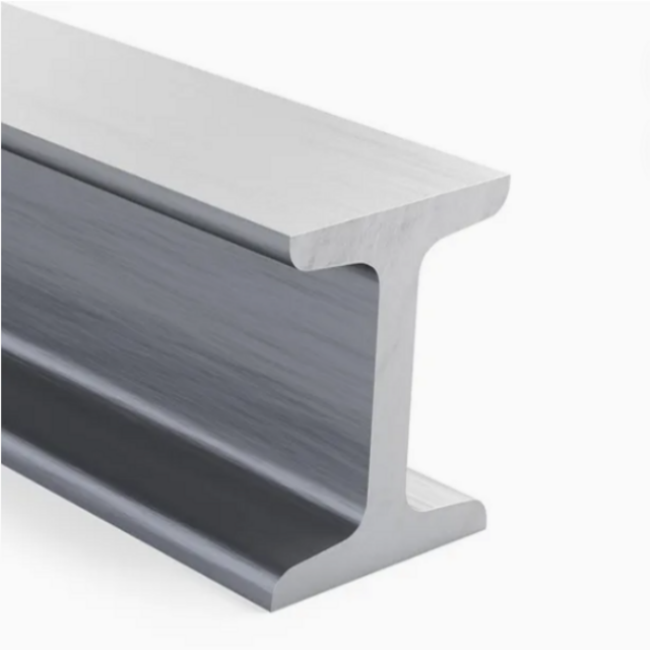

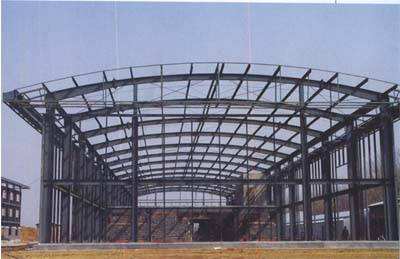

310S stainless steel I-beam

Stainless steel bar is a common stainless steel profiles, with excellent corrosion resistance, high strength and good processing performance, widely used in industry, construction, medical, food processing and other fields.

- Overview

- Recommended Products

Main Material

1.The material of stainless steel bar is usually selected according to the composition and performance requirements, and the common ones are:

2.Austenitic stainless steel: such as 304 (06Cr19Ni10), 316 (06Cr17Ni12Mo2), good corrosion resistance, non-magnetic, suitable for food, chemical, medical and other fields.

3.Martensitic stainless steel: such as 420 (20Cr13), 440 (90Cr18), high hardness, wear-resistant, commonly used in cutting tools, bearings and so on.

4.Ferritic stainless steel: such as 430 (10Cr17), oxidation resistance, low cost, but poor toughness, mostly used for decoration, home appliances.

5.Duplex stainless steel: such as 2205 (022Cr23Ni5Mo3N), both austenitic and ferritic advantages, high strength and resistance to chloride corrosion, suitable for marine, petrochemical environment.

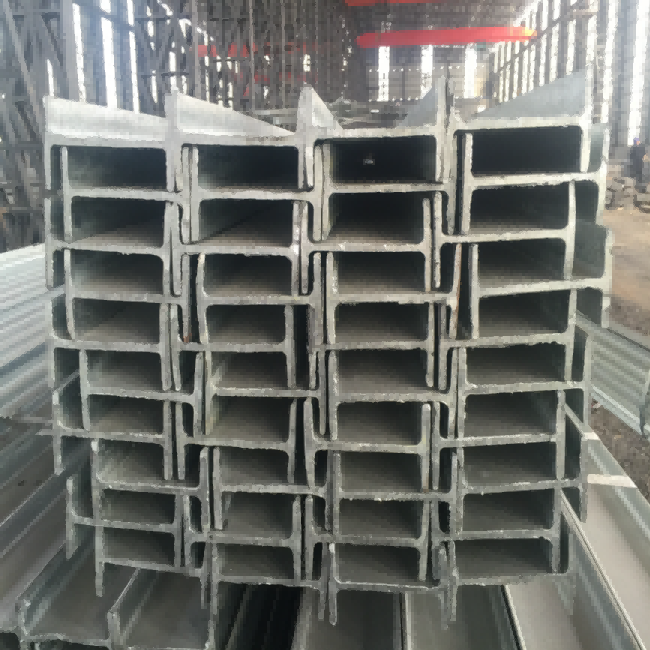

Common specifications

1.Shape: round bar, square bar, hexagonal bar, flat bar, etc.

2.Diameter/Side Length: Round bar is usually Φ1mm~Φ300mm, square bar and hexagonal bar side length is 3mm~100mm.

3.Length: Conventional straight bar length is 1m~6m, and can be customised with extra long or short size.

Production process

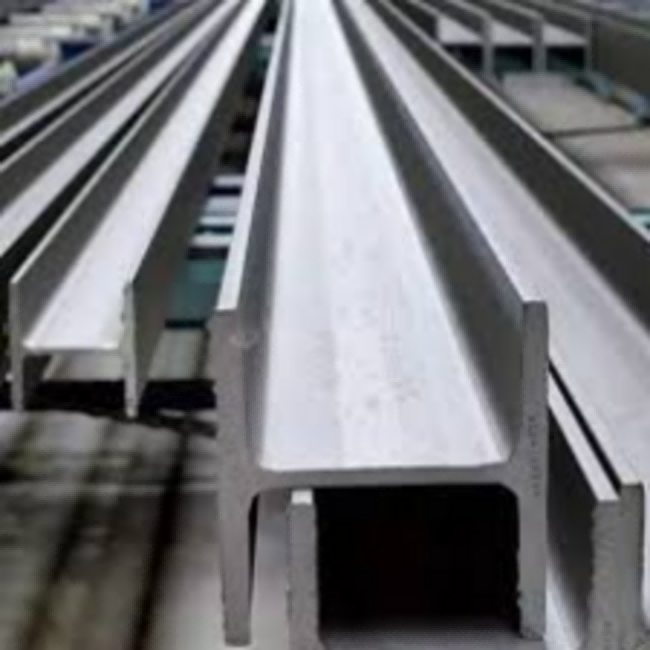

1.Hot rolling: high temperature rolling and forming, rougher surface, suitable for large size bars.

2.Cold drawing (cold rolling): room temperature processing, high dimensional accuracy, smooth surface, better mechanical properties.

3.Forging: Improve density and strength by forging, used for high load parts.

Performance characteristics

1.Corrosion resistance: chromium content ≥ 10.5% to form a passivation film, resistance to acid, alkali, salt spray corrosion (316 due to molybdenum, corrosion resistance is stronger).

2.High strength: martensitic and duplex stainless steel tensile strength up to 500MPa or more.

3.High and low temperature resistance: some grades (such as 310S) can withstand 1000 ℃ high temperature or -196 ℃ low temperature.

4.Easy processing: can be turned, milled, welded, polished, to adapt to different needs.

Application areas

1.Industry: bolts, shaft parts, pump and valve parts, chemical equipment.

2.Construction: decorative columns, handrails, curtain wall support parts.

3.Medical: surgical instruments, implants (medical grade such as 316L).

4.Food: processing equipment, conveying shaft (need food grade 304/316).

5.Energy: nuclear power, oil pipeline fittings.

Surface treatment

1.Bright surface: polished finish, beautiful and easy to clean.

2.Acid washing surface: remove oxidation layer, improve corrosion resistance.

3.Sandblasted/brushed: increase texture and reduce fingerprint residue.

Selection and Purchase Precautions

1.Material Certification: Check the standards of ASTM, GB, JIS, etc. (e.g. 304 needs to comply with ASTM A276).

2.Use of the environment: acidic environment choose 316, high temperature environment choose 310S.

3.Dimensional tolerances: precision machining need to choose cold drawn bar to ensure accuracy.

Maintenance and care

1.Regularly clean the surface stains to avoid long-term adhesion of chloride ions (such as salt).

2.After welding, the weld needs to be pickled or passivated to restore corrosion resistance.

The selection of stainless steel bar should consider the material, process and use of the scene, reasonable selection can significantly extend the service life and reduce costs.