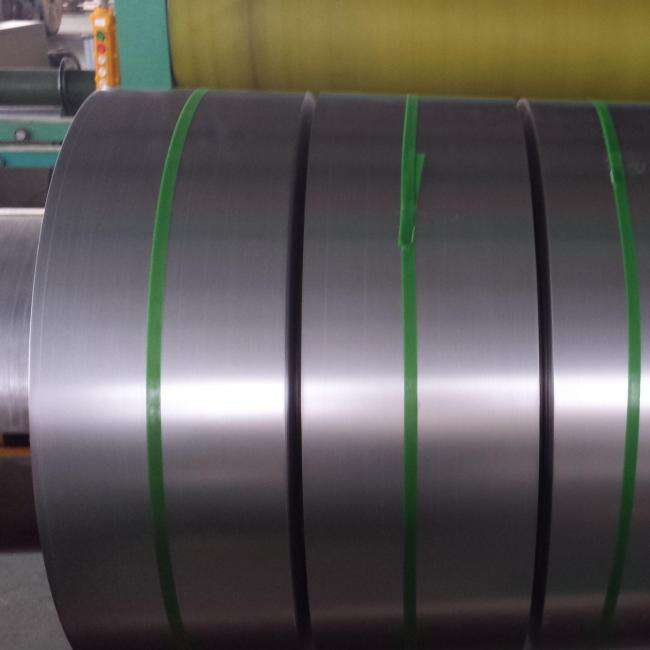

310S Stainless Steel Coil

Stainless steel coil is a common form of stainless steel products, usually made from stainless steel sheet and strip by curling and forming, easy to transport, storage and subsequent processing.

- Overview

- Recommended Products

Material and Classification

1.Stainless steel coils are mainly divided into the following categories according to different material compositions:

2.Austenitic stainless steel: such as 304 (06Cr19Ni10), 316 (06Cr17Ni12Mo2), good corrosion resistance, widely used.

3.Martensitic stainless steel: such as 410 (12Cr13), high hardness, commonly used in cutting tools, mechanical parts.

4.Ferritic stainless steel: such as 430 (10Cr17), oxidation resistance, low cost, mostly used for home appliances, decoration.

5.Duplex stainless steel: such as 2205 (022Cr23Ni5Mo3N), both high strength and corrosion resistance, used in chemical industry, marine environment.

Common specifications

1.Thickness: 0.1mm~6.0mm (thin plate coil commonly 0.3~3.0mm).

2.Width: regular 1000mm, 1219mm, 1500mm, etc., can be customised.

3.Roll weight: usually 5~20 tonnes/roll, adjustable according to thickness and width.

4.Inner diameter: the inner diameter of roll core is mostly 508mm (20 inches) or 610mm (24 inches).

Surface treatment

1.2B surface: bright annealed after cold rolling, smooth surface, most commonly used.

2.BA surface: mirror bright treatment, high reflectivity, used for high-end decoration.

3.No.1: pickled after hot rolling, rougher surface, suitable for industrial use.

4.Brushed surface (HL): texture formed by mechanical drawing, beautiful and scratch-resistant.

5.Sandblasted surface: frosted texture, commonly used in architectural decoration.

Production process

1.Hot rolling: billets are heated and rolled into thicker coils, the surface needs to be pickled to remove the oxide layer.

2.Cold rolling: hot rolled coils are cold rolled and pressed thin, with higher precision and smoother surface.

3.Annealing: Eliminate work hardening and restore material toughness.

4.Slitting/cutting: cut into different widths or flat sheets as required.

Application fields

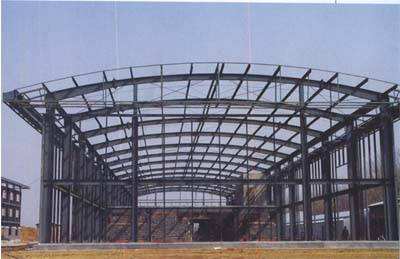

1.Building decoration: lift decoration, curtain wall, doors and windows, etc.

2.Home appliance manufacturing: refrigerator, washing machine, hood panel.

3.Food and medical treatment: kitchen equipment, surgical instruments (need 316 and other medical grade stainless steel).

4.Industrial equipment: chemical piping, storage tanks, mechanical parts.

5.Automotive industry: exhaust pipes, decorative strips (commonly used 409, 439, etc.).

Advantageous features

1.Corrosion resistance: chromium element forms a passivation film that resists acids, alkalis and humid environments.

2.High strength: hardness is enhanced after cold rolling, suitable for load-bearing structures.

3.Easy processing: can be stamped, welded and bent to adapt to a variety of processes.

4.Environmentally friendly: 100% recyclable, in line with the requirements of sustainable development.

Notes on selection and purchase

1.Confirmation of material standards: such as ASTM (American Standard), JIS (Japanese Standard), GB (National Standard).

2.Surface quality check: no scratches, indentation, colour difference and other defects.

3.Thickness tolerance: choose precision (±0.02mm) or common tolerance according to the use.

4.Anti-corrosion requirements: coastal or highly polluted areas are recommended to use 316, 2205 and other more corrosion-resistant materials.

Market Frequently Asked Questions

1.Price fluctuation: affected by the futures price of nickel, chromium and other metals.

2.Counterfeit materials: need to be detected by spectrometer composition, to avoid substandard (such as 201 pretends to be 304).