304 316 430 2205 Stainless Steel Seamless Pipe for Industry

Stainless steel seamless pipe is a kind of weldless steel pipe made by cold or hot rolling process. Main features:Weldless structure,Material Diversity,High dimensional accuracy,Resistant to extreme environments. Core Advantages:Excellent corrosion resistance,High strength and light weight,Long life and low maintenance,Hygienic safety,Processing adaptability.

- Overview

- Recommended Products

Main features

1.Weldless structure:

Adopting monolithic moulding process (such as perforation, extrusion, etc.) avoids the weak points brought by welding, and has high structural uniformity.

2.Material Diversity:

Commonly used austenitic (e.g. 304, 316), martensitic (e.g. 430) and duplex stainless steel (e.g. 2205) to adapt to different environmental needs.

3.High dimensional accuracy:

Cold rolling process can produce high precision tubes with uniform wall thickness and high surface finish.

4.Resistant to extreme environments:

Resistant to high temperatures (some grades can reach over 800°C) and high pressures, suitable for harsh working conditions.

Core Advantages

1.Excellent corrosion resistance:

Chromium (≥10.5%) forms a passivation film, and molybdenum-containing steel grades such as 316 are more resistant to corrosion by chlorine ions, which is suitable for chemical and marine environments.

2.High strength and light weight:

The tensile strength can reach 520MPa or more (such as 304), and the wall thickness is thinner than that of carbon steel pipe under the same pressure, which reduces the weight.

3.Long life and low maintenance:

Resistant to corrosion and abrasion, the service life can be up to 3 times more than ordinary steel pipe, reducing the frequency of replacement.

4.Hygienic safety:

Austenitic stainless steel is non-toxic, non-precipitated, and can be electrolytically polished to achieve medical grade cleanliness (e.g., 316L for implantable devices).

5.Processing adaptability:

Cold bending, flaring, deep machining, good welding performance (need to match welding consumables).

Specifications:

Grade |

201,304, 304L, 310s, 316L, 321,2205, 2507, 904L |

Standard |

ASTM,DIN,JIS,BS,GB,KS,EN |

OD |

6-2500MM, NPS 1/2-NPS48 |

Thickness |

1-150MM /SCH10S-XXS |

Tolerance |

±5% or as required |

Steel Grade |

301L, S30815, 301, 304N, 310S, S32305, 410, 204C3, 316Ti, 316L, 441, 316, L4, 420J1, 321, 410S, 410L, 436L, 443, LH, L1, S32304, 314, 347, 430, 309S, 304, 439, 204C2, 425M, 409L, 420J2, 436, 445, 304L, 405, 370, S32101, 904L, 444, 301LN, 305, 429, 304J1, 317L |

Surface Finish |

Blank,Pickled,Polished, annealing, brushed, H/L,6k, 8k |

Typical Application scenarios

1.Energy industry: boiler tubes (high pressure and high temperature resistant), nuclear power heat exchanger tubes.

2.Petrochemical/chemical industry: reactor piping, acid-resistant transport pipeline.

3.High-end manufacturing: ultra-clean piping for semiconductor equipment, aviation hydraulic systems.

4.Building decoration: curtain wall support structure (both load-bearing and aesthetic).

Comparison with welded pipe

| Characteristics | Seamless pipe | Welded pipe |

| strength | Higher (no heat-affected zone) | Slightly lower strength at welds |

| Pressure resistance | Suitable for ultra-high-pressure systems | Medium-low-pressure scenarios |

| Costs | Higher (complex process) | Lower (higher production efficiency) |

| Surface quality | Smoother inner and outer walls | Possible weld marks |

Selection advice:preferred seamless pipe for high-pressure, corrosive, or high-purity media scenarios; welded pipe is suitable for budget-constrained and mild working conditions projects.

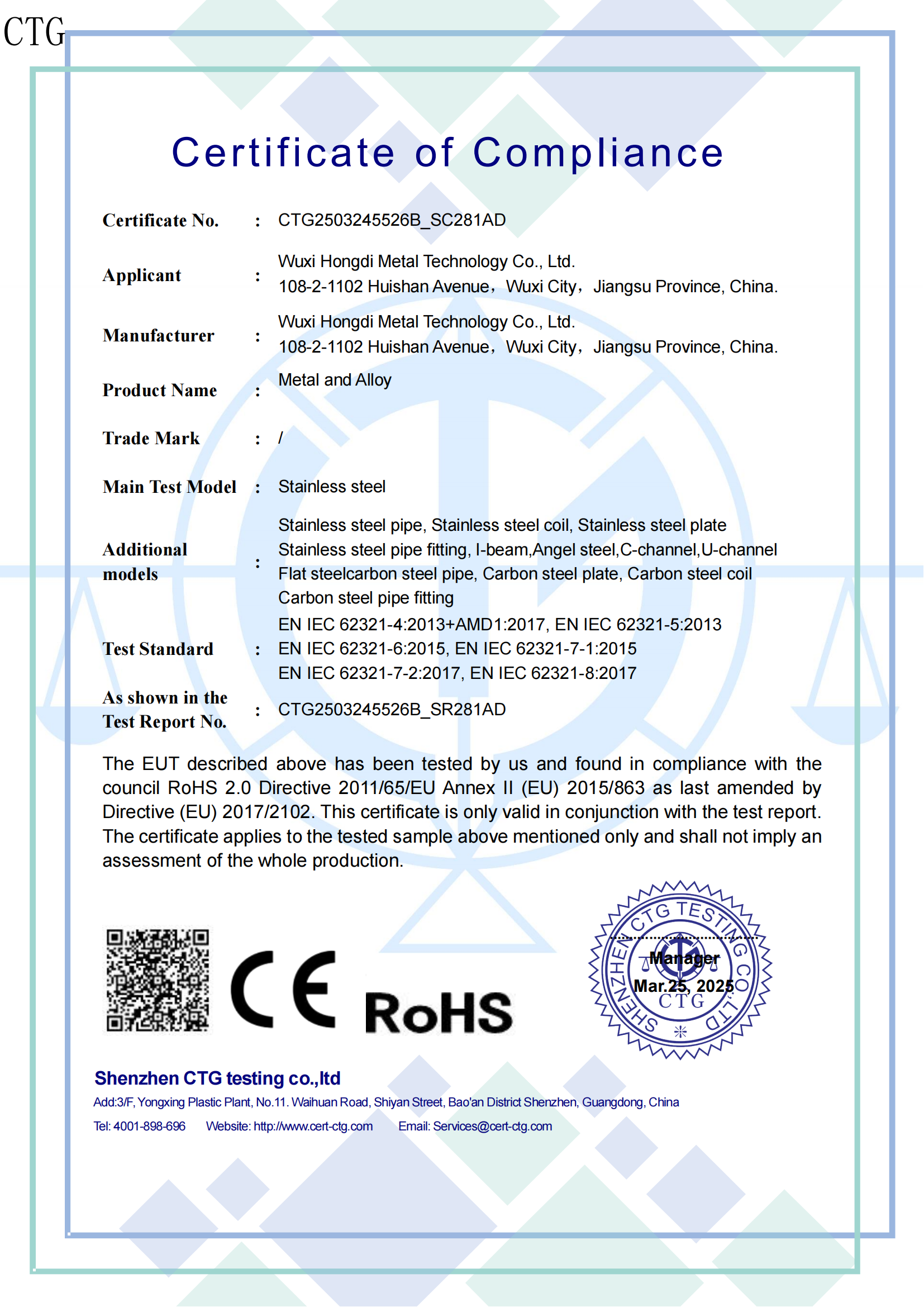

Our Certification